Project Update: Optimization Underway With Clear Path Set to Unlock Halleck Creek’s Rare Earth Potential

Rhea-AI Summary

American Rare Earths (OTCQX: AMRRY) has announced significant progress in optimizing mineral processing at its Halleck Creek Rare Earths Project's Cowboy State Mine in Wyoming. The company is conducting parallel mineral processing optimization tests focused on improving magnet rare earths recoveries through multiple comminution and beneficiation methods.

Key developments include ordering long-lead time equipment for a demonstration plant, including conventional magnetic separation equipment, and plans to commence test mining to extract ~3,200 tonnes of bulk samples. The optimization work involves testing three different comminution methods: Vertical Roller Mill, High Pressure Grinding Rolls Air Classifier, and HPGR Tower Mill.

While this additional optimization work will extend the Pre-Feasibility Study (PFS) timeline, it aims to create a more robust mineral processing flow-sheet and advance the project toward becoming a producing asset.

Positive

- None.

Negative

- Additional optimization work will delay the Pre-Feasibility Study completion

- Project still requires extensive testing before reaching production stage

News Market Reaction

On the day this news was published, AMRRY declined 1.77%, reflecting a mild negative market reaction.

Data tracked by StockTitan Argus on the day of publication.

Highlights

- Mineral Processing optimization tests underway

- Multiple parallel avenues of testing in progress with the objective of increasing overall magnet rare earths recoveries

- Long lead time equipment ordered for a demonstration plant

- Conventional magnetic separation equipment ordered, a critical component of a demonstration plant

- Test mining set to commence

- Test mining at the Cowboy State Mine to provide bulk samples for optimization test work and feedstock for a demonstration plant

DENVER, July 18, 2025 (GLOBE NEWSWIRE) -- American Rare Earths (ASX: ARR | OTCQX: ARRNF | ADR: AMRRY) (“ARR” or the “Company”), is pleased to provide an update on project activities at Cowboy State Mine (“CSM”), part of the Halleck Creek Rare Earths Project in Wyoming.

American Rare Earths, through its subsidiary Wyoming Rare (USA) Inc. (“WRI”), will be performing a series of additional mineral processing optimization tests for the Cowboy State Mine’s Pre-Feasibility Study (“PFS”).

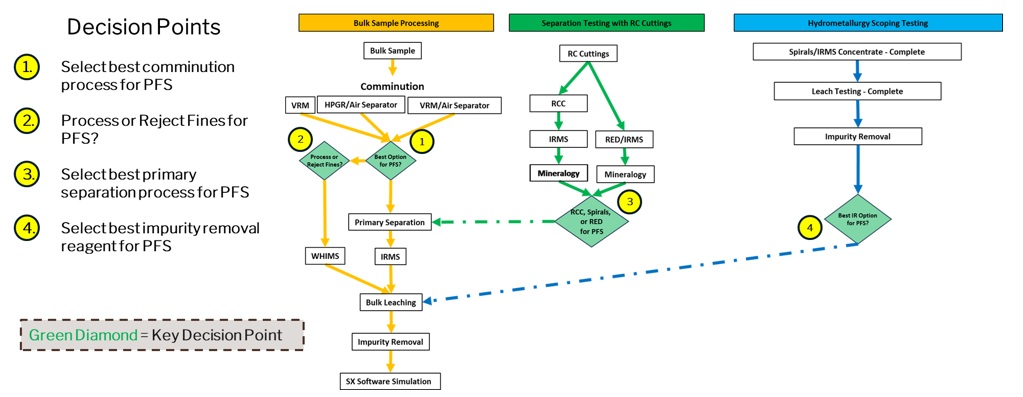

The additional work will occur in parallel to current planned mineral processing tests and includes testing multiple comminution (i.e. milling) methods and optimizing the beneficiation circuit (i.e. mineral separation and concentration). Figure 1 outlines the road map of the mineral processing optimization work underway.

In addition, the Company has already ordered long-lead time equipment for a demonstration plant and will commence test mining in the immediate term to extract the necessary feedstock for the future facility. The optimization work and demonstration plant are key steps forward in producing rare earth magnet oxides from Halleck Creek ore.

Why it matters? In general terms, a PFS is a key milestone to demonstrate, at a relatively high confidence level1 , the technical and economic viability of a project. The study is essentially a blue-print, backed by extensive laboratory test data, for the mine and mineral processing plant. A well-executed and robust PFS typically provides potential investors, strategic partners, creditors and off-take parties with confidence in the project’s production potential and underlying economics. In addition, it lays the foundation for future studies (i.e. Definitive Feasibility Study) which can lead to construction and development decisions. It is a key step in de-risking the project from a technical and economic standpoint, which, if successful, can move a development project one step closer to becoming a producing asset.

The objective of the comminution and beneficiation optimization testing is to find optimal and conventional processing methods to further increase the recovery of rare earth minerals. This additional optimization work sets a clear path for American Rare Earths to produce a robust mineral processing flow-sheet for the PFS and ultimately unlock Halleck Creek’s immense rare earths potential.

Once complete, the Company can also use the flow-sheet design as a blue-print for a demonstration plant to showcase and fine-tune the process at a larger scale. Given the confidence in the Halleck Creek project, steps to progress the demonstration plant have already commenced in parallel to the optimization work. However, most of the optimization work is in addition to the original PFS scope and as a result will extend the CSM PFS publication.

Summary of Optimization Work Underway:

- Test Mining: The Company will exercise its License to Explore2 to collect bulk samples required to perform comminution tests. Approximately 8 tonnes are required for the comminution testing, however given the extraction equipment will be mobilized on site, the Company plans to extract ~3,200 tonnes to also fulfil the future demonstration plant feedstock needs.

- Comminution: Reducing the proportion of fines (i.e. very fine material, ore milled below 50 microns) entering the beneficiation circuit enhances overall ore concentration and increases the total rare earth oxide (“TREO”) grade into leach. Reducing fines can reduce reagent consumption during leaching and impurity removal, which can potentially lower operating costs.

- Three different comminution methods will be tested: Vertical Roller Mill (“VRM”), High Pressure Grinding Rolls (“HPGR”) Air Classifier and a HPGR Tower Mill.

- Beneficiation: Induced Roll Magnetic Separators (“IRMS”) are the most effective method of separating allanite (i.e. rare earth host mineral) from gangue (i.e. material with no REE mineralization) material3 tested to date. This equipment will be used in the mineral processing flow sheet, however the primary separation method (i.e. pre-IRMS processing step) has room to be optimized.

- Hydrometallurgy: Extensive scoping leach tests have already been completed and the leach parameters are well defined4. However, impurity removal (i.e. processing step after leaching) tests are currently underway. Once comminution and beneficiation process optimization testing concludes, bulk samples will be generated using the preferred grinding and separation options to run larger scale leach and impurity removal tests.

This release was authorized by the board of American Rare Earths.

Investors can follow the Company’s progress at www.americanree.com.

_______________

1 PFS-level engineering estimates are typically classified as a Class 4 estimate according to the Association for Advancement of Cost Engineering International (AACEI), which aligns with this ±

2 See ASX Release dated January 8, 2025 for additional details.

3 See ASX Release dated February 20, 2025 for additional details.

4 See ASX release dated July 16, 2025.

About American Rare Earths Limited:

American Rare Earths (ASX: ARR | OTCQX: ARRNF | ADR: AMRRY) is a critical minerals company at the forefront of reshaping the U.S. rare earths industry. Through its wholly owned subsidiary, Wyoming Rare (USA) Inc. (“WRI”), the company is advancing the Halleck Creek Project in Wyoming—a world-class rare earth deposit with the potential to secure America’s critical mineral independence for generations. Located on Wyoming State land, the Cowboy State Mine within Halleck Creek offers cost-efficient open-pit mining methods and benefits from streamlined permitting processes in this mining-friendly state.

With plans for onsite mineral processing and separation facilities, Halleck Creek is strategically positioned to reduce U.S. reliance on imports—predominantly from China—while meeting the growing demand for rare earth elements essential to defense, advanced technologies, and economic security. As exploration progresses, the project’s untapped potential on both State and Federal lands further reinforces its significance as a cornerstone of U.S. supply chain security. In addition to its resource potential, American Rare Earths is committed to environmentally responsible mining practices and continues to collaborate with U.S. Government-supported R&D programs to develop innovative extraction and processing technologies for rare earth elements.

For additional information:

Susan Assadi

Media Relations US

sassadi@americanree.com

347 977 7125

Beverly Jedynak

Investor Relations US

Beverly.jedynak@viriathus.com

312 943 1123

Figure 1 - Illustrative Mineral Processing Optimization Road Map5

Note: SX = Solvent Extraction, RC = Reverse Circulation

_______________

5 See ASX Release dated February 20, 2025 and July 16, 2025 for additional details.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/4fe602f9-397c-4081-9ec4-b59fd61f11f4