Avalon and Engina Successfully Recovered 15 Rare Earth Elements with Breakthrough Processing Technology for Nechalacho Project, NWT Canada

Rhea-AI Summary

Avalon (OTCQB: AVLNF) and Engina announced a technology assessment (November 2025) showing Engina's Hybrid Supercritical Refining (HSR) achieved overall rare earth recoveries exceeding 90% in preliminary bench-scale tests on Nechalacho concentrate.

The HSR flowsheet integrates a caustic pretreatment with supercritical CO2 extraction in a largely closed-loop, water-lean design that modelling indicates can eliminate sulphuric acid plant needs, reduce neutralization waste and lower specific energy intensity versus conventional acid-bake/water-leach and caustic-cracking routes. A multi-phase roadmap toward pilot (TRL 7-8) and feasibility work is planned.

Positive

- Recoveries >90% reported in bench-scale testing

- Process model eliminates need for sulphuric acid plant and sulphate tailings

- Modelling indicates lower specific energy intensity than ABWL or caustic-cracking

- Water-lean, closed-loop design reduces reagent use and environmental load

Negative

- Results are preliminary bench-scale tests pending pilot validation

- Optional zirconium/niobium recovery routes are not yet experimentally validated

- Commercial integration depends on techno-economic and pilot studies before deployment

News Market Reaction

On the day this news was published, AVLNF gained 11.53%, reflecting a significant positive market reaction.

Data tracked by StockTitan Argus on the day of publication.

Engina's proprietary Hybrid Supercritical Refining process delivers >

Toronto, Ontario--(Newsfile Corp. - November 24, 2025) - Avalon Advanced Materials Inc. (TSX: AVL) (OTCQB: AVLNF) ("Avalon" or the "Company") and Engina Corporation ("Engina") have completed a joint assessment confirming that Engina's proprietary Hybrid Supercritical Refining (HSR) process, a next-generation rare earth extraction technology that can deliver breakthrough performance for Avalon's Nechalacho in the Northwest Territories, Canada.

The assessment confirms that Engina's next-generation hydrometallurgical process, which integrates a unique caustic pretreatment together with supercritical fluid extraction, demonstrated overall rare earth recoveries exceeding

The assessment was led by internationally recognized Dr. Gisele Azimi of Engina Corporation. Azimi, P.Eng., is a leading expert in hydrometallurgical process innovation and advanced materials engineering.

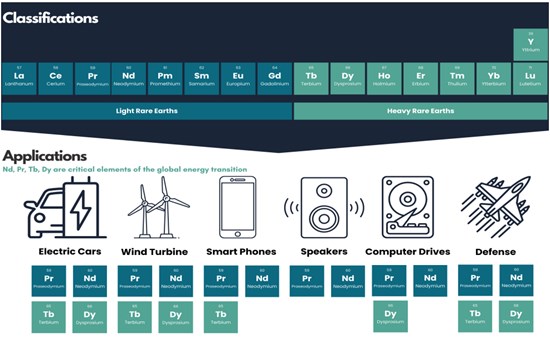

Figure 1: Uses of Light and Heavy Rare Earth Elements (REEs)

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/3386/275564_34748974c4056926_001full.jpg

Transformative Results and Environmental Benefits

The HSR process represents a step-change in rare earth extraction technology. It is designed as a largely closed-loop, water-lean system. Based on modelling and design targets the process is designed to eliminate the need for sulphuric acid-plant operations, associated emissions and sulphate tailings, and produce near-neutral, non-hazardous solids. Based on the modelling results the process significantly reduces neutralization waste compared with existing hydrometallurgical circuits and operates with minimal combustion and no sulphuric acid handling, minimizing greenhouse-gas emissions and improving worker safety. This innovative method, leveraging well understood and proven separation technology from other process intensive industries uses recycled CO₂ as the principal extraction solvent.

The initial design and simulations developed by Engina show that the hybrid circuit is expected to offer a lower specific energy intensity than the ABWL or traditional caustic-cracking processes and may be evaluated for integration in Avalon's Pine Point envisioned plant pending successful pilot-scale validation and subsequent engineering studies.

While the current HSR flowsheet delivered in the Technology Assessment focuses on rare earth extraction, the process modelling indicates that the caustic pretreatment step converts zirconium- and niobium-bearing minerals into reactive forms. Optional downstream unit operations - which are not part of the current HSR configuration and have not yet been experimentally validated - could be developed to selectively recover these accessory critical minerals. These pathways may be evaluated in future engineering phases based on technical feasibility and economic merit.

Strategic Collaboration with Avalon

The Nechalacho Project, one of Canada's major rare earth projects, provides Avalon with an opportunity to establish a sustainable, low-carbon supply chain for critical materials essential to clean-energy, medical, and defence technologies. Engina's work supports Avalon's commitment to next-generation, low-impact processing that enhances Canada's position in the global rare earth market and exemplifies Canadian-led innovation in critical mineral processing.

Scott Monteith, President and CEO commented, "We are very thrilled for this breakthrough in the extraction of some of the most crucial rare earth elements (REE). We live in a world today that clearly indicates the urgent need for REE and to avoid the dominance of a single producer nation. With a feasibility study that was completed in 2013 and approximately

Dr. Gisele Azimi of Engina Corporation commented, "The Hybrid Supercritical Refining platform offers Avalon a genuinely new pathway for responsible rare earth extraction. Achieving high recoveries while reducing reagent use and environmental load is a rare combination in our industry. We are pleased with the initial results and are committed to working with Avalon to advance the systematic testing required to determine the technology's full commercial potential."

Next Steps Toward Commercialization

The Technology Assessment Report, delivered to Avalon in November 2025, outlines a multi-phase development roadmap:

- Bench-scale variability testing using multiple Nechalacho concentrate samples to confirm performance across ore types.

- Integrated continuous mini-loop operation to validate mass and energy balances and solvent recyclability.

- Techno-economic and environmental assessment, leading to pilot design.

- Continuous pilot plant (TRL 7-8) and full feasibility study to support commercial deployment.

These next steps will establish the design basis for Avalon's future rare earth recovery facilities and reinforce Engina's position as a technology partner of choice for sustainable critical mineral extraction.

Qualified Person and NI43-101 Disclosure:

The scientific and technical data contained in this news release were reviewed and approved by Dr. Gisele Azimi, P.Eng., a non-independent "Qualified Person" under the National Instrument 43-101 Standards of Disclosure of Mineral Projects.

IP and Legal Disclaimer

The Hybrid Supercritical Refining (HSR) process referenced in this release is proprietary to Engina Corporation and is patent-protected and patent-pending. No rights or licenses to Engina intellectual property are granted or implied by this release.

About Engina Corporation

Engina Corporation is a Canadian technology and engineering company specializing in innovative metallurgical, chemical, and energy systems. Engina's proprietary HSR platform offers a cleaner, closed-loop alternative to conventional hydrometallurgical processing of complex ores. The company provides R&D, process-design, and techno-economic evaluation services to the mining, energy, and materials industries. For more information, please visit www.engina.ca or email info@engina.ca.

About Avalon Advanced Materials Inc.

Avalon Advanced Materials Inc. is a Canadian critical minerals company advancing the supply of materials essential to a resilient North American supply chain. The Company is focused on developing strategic assets that support secure, domestic supply chains and long-term economic growth. Avalon is advancing the Nechalacho Rare Earth Elements and Zirconium Project in the Northwest Territories, which contains all light and heavy rare earth elements, as well as yttrium, zirconium, tantalum, and niobium—critical minerals used in advanced technologies across the communications, defense, clean tech, and energy sectors. The Company is also focused on vertically integrating the Ontario lithium supply chain through the development of Lake Superior Lithium Inc., Ontario's first midstream lithium hydroxide processing facility, located in Thunder Bay. This facility will serve as a vital link between northern Ontario's lithium resources and the growing EV battery manufacturing base in southern Ontario and North America. Through a joint venture with SCR Sibelco NV, Avalon is advancing the Separation Rapids Lithium Project near Kenora, Ontario, as well as continuing exploration at its Snowbank lithium and Lilypad lithium-cesium deposits.

For further information regarding Avalon Advanced Materials Inc., please visit www.avalonadvancedmaterials.com, email ir@avalonam.com, or call 416-364-4938.

Cautionary Statement Regarding Forward-Looking Information

This news release contains "forward-looking information" within the meaning of applicable Canadian securities legislation. Forward-looking information includes, but is not limited to, statements related to project development plans, pilot programs, and potential performance of proprietary processes. Generally, forward-looking information can be identified by the use of forward-looking terminology such as "add" or "additional", "advancing", "anticipates" or "does not anticipate", "appears", "believes", "can be", "conceptual", "confidence", "continue", "convert" or "conversion", "deliver", "demonstrating", "estimates", "encouraging", "expand" or "expanding" or "expansion", "expect" or "expectations", "forecasts", "forward", "goal", "improves", "increase", "intends", "justification", "plans", "potential" or "potentially", "promise", "prospective", "prioritize", "reflects", "robust", "scheduled", "suggesting", "support", "top-tier", "updating", "upside", "will be" or "will consider", "work towards", or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might", or "will be taken", "occur", or "be achieved".

Forward-looking information is subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of the Company to be materially different from those expressed or implied by such forward-looking information, including risks associated with mineral exploration and development operations such as: environmental hazards and economic factors as they affect the cost and success of the Company's capital expenditures, the ability of the Company to obtain required permits and approvals, the ability of the Company to obtain financing, uncertainty in the estimation of mineral resources, uncertainty with respect to the ability to successfully construct and develop the Company's lithium processing facility, the price of lithium, no operating history, no operating revenue and negative cash flow, land title risk, the market price of the Company's securities, the economic feasibility of the Company's mineral resources and the Company's commercial viability, inflation and uncertain global economic conditions, uncertain geo-political shifts and risks, successful collaboration with indigenous communities, changes in technology and advancements in innovation may impact the development of the Company's technology innovation centre and its lithium hydroxide processing facility, future pandemics and other health crises, dependence on management and other highly skilled personnel, title to the Company's mineral properties, the ongoing war in Ukraine and Israel, extensive government and environmental regulation, reliance on artificial intelligence technology to influence mining operations, volatility in the financial markets, uninsured risks, climate change, threat of legal proceedings, as well as those risk factors discussed or referred to in the annual information form of the Company dated November 28, 2024 (the "AIF") under the heading "Description of the Business - Risk Factors". Forward-looking information is based on the reasonable assumptions, estimates, analysis and opinions of management made in light of its experience and perception of trends, current conditions and expected developments, as well as other factors that management believes to be relevant and reasonable in the circumstances at the date that such statements are made, but which may prove to be incorrect. Although the Company believes that the assumptions and expectations reflected in such forward-looking information are reasonable, undue reliance should not be placed on forward-looking information because the Company can give no assurance that such expectations will prove to be correct. In addition to other factors and assumptions identified in the AIF, assumptions have been made regarding, among other things: management of certain of the Company's assets by other companies or joint venture partners, the Company's ability to carry on its exploration and development activities without undue delays or unbudgeted costs, the ability of the Company to obtain sufficient qualified personnel, equipment and services in a timely and cost effective manner, the ability of the Company to operate in a safe, efficient and effective manner, the ability of the Company to obtain all necessary financing on acceptable terms and when needed, the accuracy of the Company's resource estimates and geological, operational and price assumptions on which these are based and the continuance of the regulatory framework regarding environmental manners. Readers are cautioned that the foregoing list is not exhaustive of all factors and assumptions that may have been used. Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such information will prove to be accurate, as actual results and future events could differ materially from those anticipated in such information. Accordingly, readers should not place undue reliance on forward-looking information. The Company does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/275564