Understanding VOC Emissions: Importance of Reduction and Cummins' Progress

Rhea-AI Summary

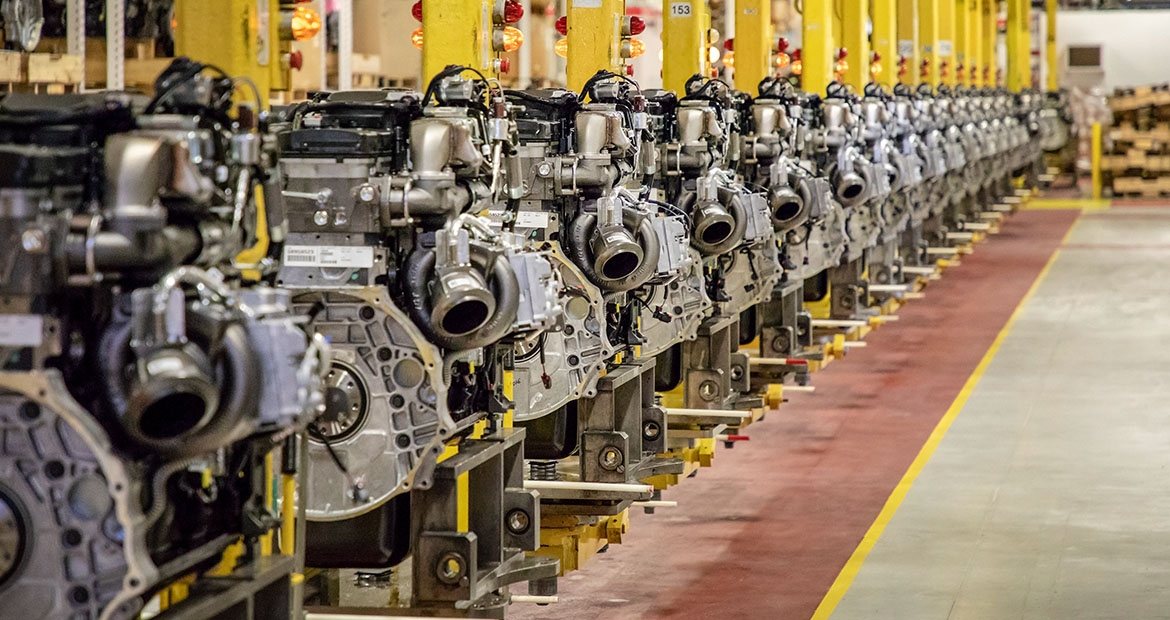

Cummins Inc. reports significant progress in reducing Volatile Organic Compounds (VOC) emissions, achieving a 35% reduction as of 2023 towards their 2030 goal of 50% reduction from 2018 levels. Over 70% of the company's VOC emissions come from painting and coating processes. The company implements various reduction strategies including: eliminating paint usage where possible, switching to waterborne paints, and optimizing painting processes. Notable achievements include a 69% VOC reduction at the Daventry Engine Plant and development of new paint filters at Jamestown Engine Plant reducing waste by 30%. The Darlington Engine Plant aims for 70% VOC reduction through water-based paint conversion.

Positive

- 35% reduction in VOC emissions achieved towards 50% 2030 target

- 69% year-over-year VOC reduction at Daventry Engine Plant

- 30% reduction in filter waste at Jamestown Engine Plant

- 10% annual paint reduction achieved through improved robot programming

- 80% reduction in service claims with new waterborne paints

Negative

- Recent acquisitions have slowed VOC reduction goal progress

News Market Reaction 1 Alert

On the day this news was published, CMI gained 2.19%, reflecting a moderate positive market reaction.

Data tracked by StockTitan Argus on the day of publication.

By Cummins Inc., Global Power Technology Leader

NORTHAMPTON, MA / ACCESSWIRE / November 21, 2024 / Cummins Inc.

Cummins

Volatile organic compounds (VOCs) are emitted as gases from a variety of products and processes, including paint and coating operations.

While paint can provide protection and aesthetic benefits to products, the VOCs emitted during the painting process also have environmental implications. VOCs can react with nitrogen oxide when exposed to sunlight to create ground-level ozone, contributing to smog. Painting operations also contribute to water and chemical waste and increased electricity and gas usage.

What is Cummins doing about VOC emissions?

Over

Reducing VOC emissions by eliminating the use of paint

Sometimes, the best solution is also the simplest. That's what a team of sustainability leaders and engineers from the Cummins Columbus Mid-Range Engine Plant (CMEP) discovered in 2020 when they first studied whether they could stop painting their engines.

Material science has evolved since Cummins engines began leaving CMEP over thirty years ago. What used to be made from grey iron that needed rust and corrosion-preventive coatings is now made from composites, aluminum and cast iron, which has better rust prevention capabilities. The CMEP team validated that eliminating paint from the engines would not lead to excess corrosion, ensuring the same engine performance, quality, capability and durability. By eliminating paint from these engines, the site was also able to reduce the energy, waste and water associated with the painting process.

Reducing VOC emissions by switching to waterborne paints and resins

Another effective approach to reducing VOC emissions is switching to waterborne paints. Solvent-based and waterborne paints have similar performance characteristics, but unlike traditional solvent-based paints which emit VOCs during the drying process, waterborne paints use water as the carrier for paint pigments, binders and additives. Since 2013, the Cummins Jamestown Engine Plant (JEP) in New York has used waterborne paints to comply with emissions requirements and reduce pollution.

Across the Atlantic, Cummins plants in the U.K. are also embracing waterborne paints. In 2023, Cummins' Daventry Engine Plant began to see the benefits of this transition. Not only did it reduce VOC emissions by

Reducing VOC emissions through process optimization

For sites that have already transitioned to waterborne paints, improvements continue to be made through process optimization. Process optimization focuses on improving efficiency by reducing overspray and excessive paint usage, reducing waste generation, reducing energy by optimizing pre- and post- operations.

After JEP transitioned to low-VOC waterborne paint, the plant continued seeking ways to further minimize its environmental impact. In 2023, new long-lasting paint filters were developed, reducing filter waste by approximately

Cummins, a global power technology leader, is a corporation of complementary business segments that design, manufacture, distribute and service a broad portfolio of power solutions. The company's products range from internal combustion, electric and hybrid integrated power solutions and components including filtration, after treatment, turbochargers, fuel systems, controls systems, air handling systems, automated transmissions, electric power generation systems, microgrid controls, batteries, electrolyzers and fuel cell products.

View additional multimedia and more ESG storytelling from Cummins Inc. on 3blmedia.com.

Contact Info:

Spokesperson: Cummins Inc.

Website: https://www.3blmedia.com/profiles/cummins-inc

Email: info@3blmedia.com

SOURCE: Cummins Inc.

View the original press release on accesswire.com