First Atlantic Nickel Reports Phase 2X Results from Pipestone XL Nickel Alloy Project: Drilling Proves 800 Meters of Newly Expanded 4km Target at RPM Zone, Doubling Strike Length

Rhea-AI Summary

First Atlantic Nickel (OTCQB: FANCF / TSXV: FAN) reported DTR metallurgical results from drill hole AN-25-08 at the RPM Zone, Pipestone XL, on Oct 23, 2025. AN-25-08 returned 480 m averaging 1.35% Ni in magnetic concentrate with an 8.79% mass pull, yielding 0.12% magnetically recoverable Ni over 480 m. This hole doubled the drill-confirmed strike to 800 m within a newly outlined 4-km continuous target, with Phase 2X drilling validating ~20% of that strike. DTR also shows Cr (1.27–2.30% in concentrate) and Co are recovered as byproducts. The company says the refined westward-dip structural model will guide eastward-oriented drilling to test true width and the remaining ~3.2 km of untested target.

Positive

- Drill-confirmed strike length doubled to 800 m

- AN-25-08: 480 m at 1.35% Ni magnetic concentrate (8.79% mass pull)

- Phase 2X validated ~20% of the 4 km RPM target area

- Magnetic concentrate contains Cr 1.27–2.30% and recoverable Co

Negative

- Magnetically recoverable nickel grade is modest at 0.12% DTR Ni over 480 m

- Approximately 3.2 km of the 4-km RPM target remains untested by drilling

- Earlier westward-oriented holes were sub-optimal, requiring re-drilling to test true width

- AN-25-08 total Ni recovery reported at 51.94%, indicating processing recovery limits

News Market Reaction 1 Alert

On the day this news was published, FANCF gained 2.95%, reflecting a moderate positive market reaction.

Data tracked by StockTitan Argus on the day of publication.

Drill Hole AN-25-08 Returns

GRAND FALLS-WINDSOR, Newfoundland and Labrador, Oct. 23, 2025 (GLOBE NEWSWIRE) -- First Atlantic Nickel Corp. (TSX-V: FAN) (OTCQB: FANCF) (FSE: P21) ("First Atlantic" or the "Company") is pleased to announce Davis Tube Recovery (DTR) metallurgical test results from drill hole AN-25-08, the seventh drill hole at the RPM Zone within its Pipestone XL Nickel Alloy Project in central Newfoundland. The DTR testing yielded a magnetic concentrate averaging

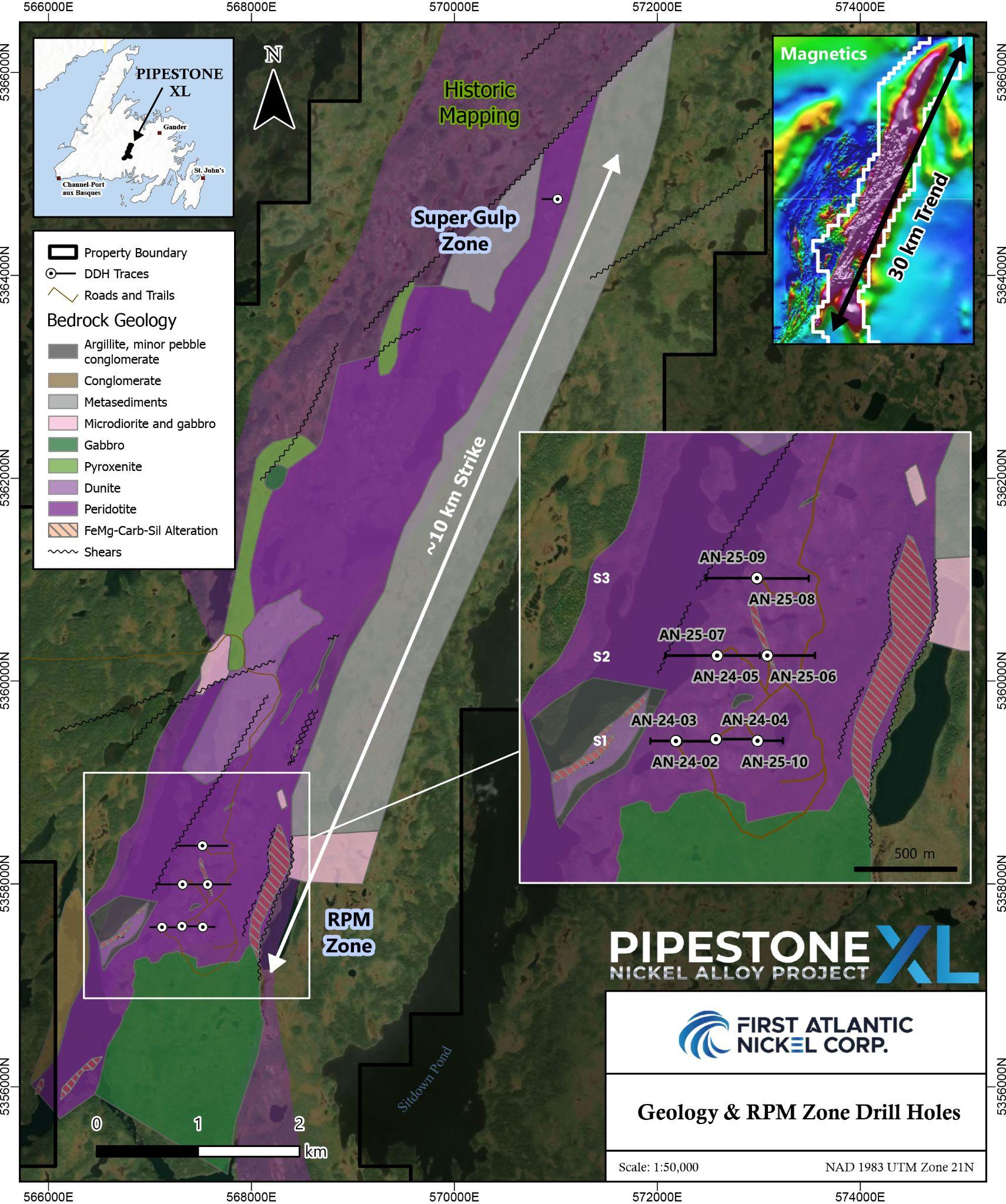

Drill hole AN-25-08, collared on Section Line S3, successfully doubled the drill-confirmed strike length of the RPM Zone to 800 meters within a newly expanded 4-kilometer continuous target area. This 4-kilometer target zone was outlined through DTR surface sampling and geological mapping announced on October 21, 2025, demonstrating the continuity of awaruite nickel mineralization along strike throughout the RPM Zone. Phase 2X drilling has now drill-confirmed 800 meters of this 4-kilometer target area, with drilling confirming magnetically recoverable awaruite nickel alloy mineralization in all holes drilled to date.

Drill results confirming 800 meters in strike length of magnetically recoverable nickel-alloy mineralization within the expanded 4-kilometer RPM Zone target area represents a significant milestone in defining the large-scale potential of the Pipestone XL Nickel Alloy Project. Integration of Phase 2X drilling results with surface sampling and improved geological mapping has refined the Company's understanding of the westward-dipping ultramafic body hosting awaruite mineralization, positioning future drilling to effectively test the true width and depth extent of the mineralized system.

KEY POINTS:

1. Hole AN-25-08 Doubles RPM Zone Strike Length to 800 Meters

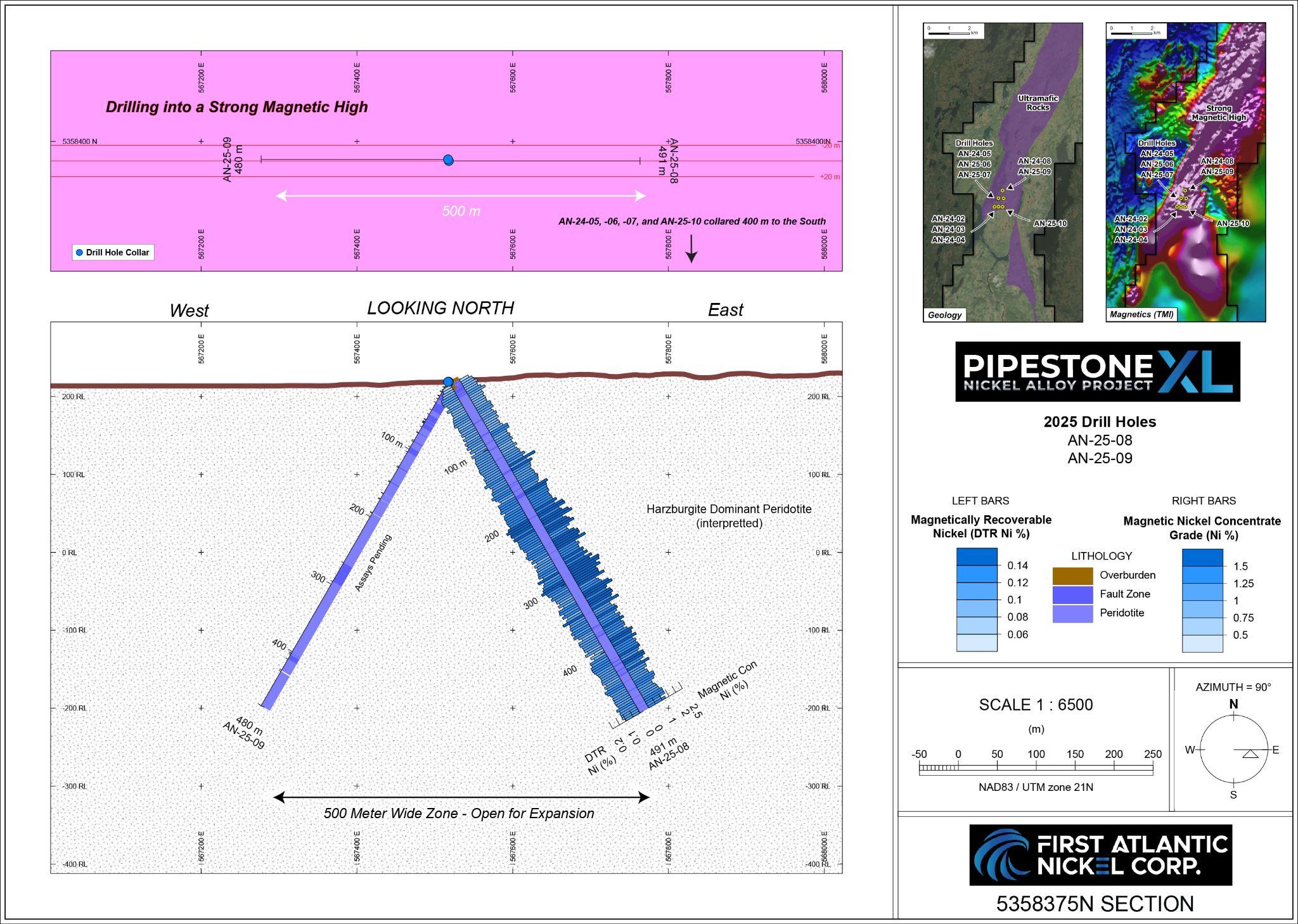

Drill hole AN-25-08, drilled on Section Line S3, approximately 400 meters north of Section S1, has successfully doubled the drill-confirmed strike length of the RPM Zone from 400 meters to 800 meters. The hole returned 480 meters averaging

2. RPM Zone - Now a 4-Kilometer Target

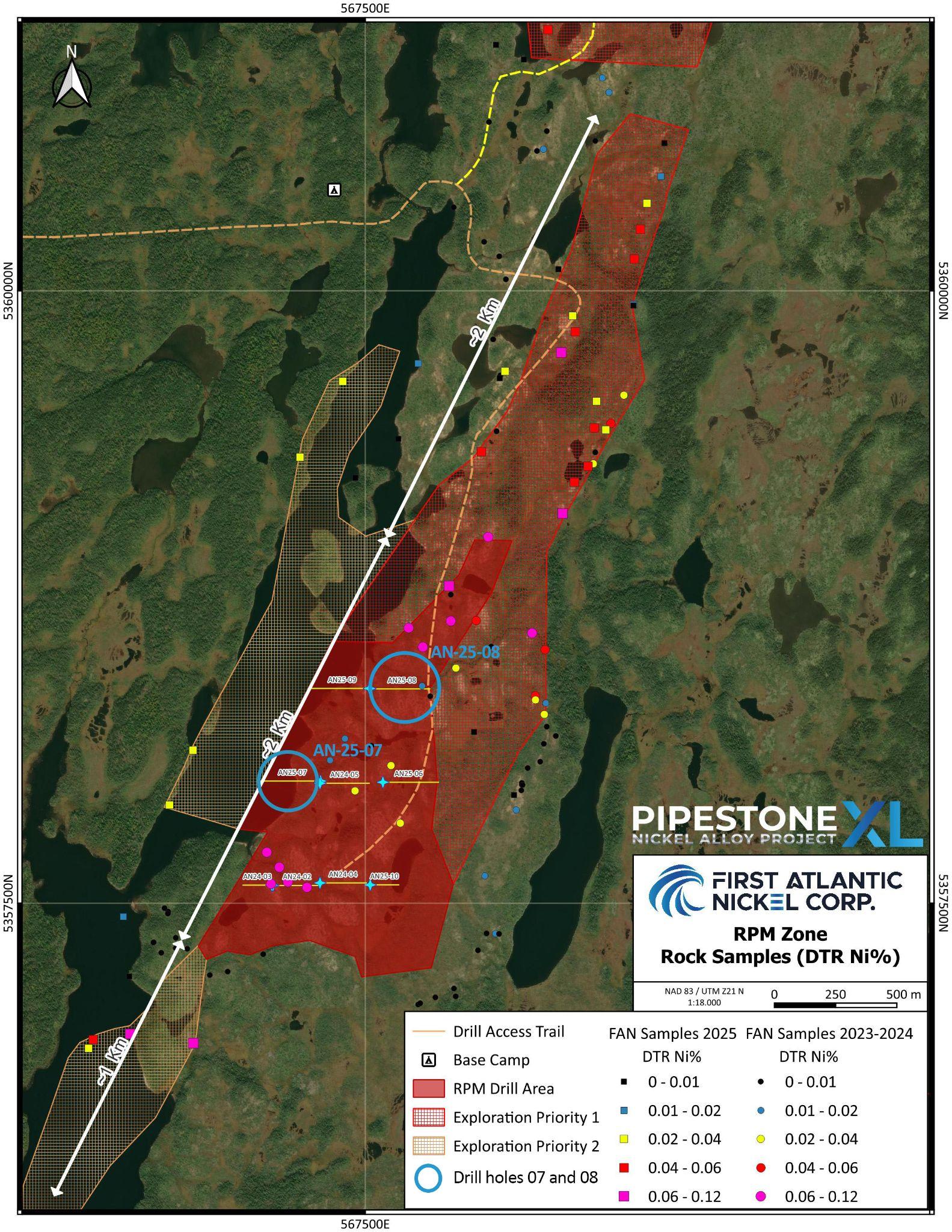

The RPM Zone now encompasses an expanded 4-kilometer continuous target area defined through DTR surface sampling and geological mapping (announced October 21, 2025). Phase 2X drilling has successfully drill-confirmed 800 meters of this 4-kilometer target zone, with all drill holes confirming magnetically recoverable awaruite nickel mineralization. The remaining ~3.2 kilometers of the target area, including a 2-kilometer northern extension designated as Exploration Priority 1 (See Figure 2), presents significant expansion potential for future drilling programs. This expanded target area reinforces the district-scale nature of the Pipestone XL Nickel Alloy Project.

3. Hole AN-25-07 Returns Consistent DTR Despite Sub-Optimal Orientation

Drill hole AN-25-07, drilled on Section Line S2 with a westward orientation prior to refined structural interpretation, successfully returned 486 meters grading

4. Structural Understanding Optimizes Future Drilling

Phase 2X drilling results from holes AN-25-07 and AN-25-08 have refined the Company's understanding of the westward-dipping ultramafic system hosting awaruite mineralization. Based on the updated structural model, AN-25-08 was oriented eastward to effectively cross-cut the mineralized structure. The successful DTR results from AN-25-08, compared with the sub-optimal westward orientation of AN-25-07, confirm that eastward-oriented drilling is essential to test the true width of the mineralized body. This refined structural model will improve the effectiveness of future drilling across the project, ensuring holes properly intersect the awaruite-bearing structure.

5. Significant Expansion Potential Within 4-Kilometer Target

The Company's systematic DTR surface sampling program has successfully outlined an expanded 4-kilometer RPM Zone target area, with Phase 2X drilling consistently confirming magnetically recoverable nickel grades multiple times higher than weathered surface samples. Recent DTR surface sampling (announced on October 21, 2025) identified multiple priority expansion opportunities, including: (1) a ~2 kilometer northern extension of the RPM Zone (Exploration Priority 1) (2) a ~1 kilometer southern extension in areas previously mapped as submarine volcanics, now reclassified as ultramafic peridotites (Exploration Priority 2); and (3) ~1.2 kilometers in total width potential supported by positive DTR results from peridotite outcrops west of Pipestone Pond. The strong correlation between surface sampling and drill results provides confidence in the additional ~3.2 kilometers of the newly outlined target area and demonstrates the significant growth potential of the RPM Zone.

6. Super Gulp Zone Requires Eastward Drilling Orientation

The refined understanding of the westward-dipping structure developed through Phase 2X drilling and geological mapping will be applied to retarget the Super Gulp Zone, located ~10 kilometers north of the RPM Zone discovery (See Figure 1). Previous westward-oriented drilling at Super Gulp, conducted before the structural interpretation was refined, likely did not optimally intersect the property-wide westward-dipping awaruite body and may have drilled along layers down-dip rather than cutting across the true width of the mineralized body. Future eastward-oriented drilling at Super Gulp is expected to effectively test the true width of the awaruite-bearing structure, providing a significant opportunity for discovery in this highly prospective area of the Pipestone XL Nickel Alloy Project.

7. Metallurgical Process Program - Magnetic Concentrate and Critical Mineral Byproducts

DTR testing has demonstrated that chromium and cobalt are magnetically recovered and concentrated alongside nickel within the awaruite-bearing magnetic concentrate, with chromium values ranging from

For further information, questions, or investor inquiries, please contact Rob Guzman at First Atlantic Nickel by phone at +1-844-592-6337 or via email at rob@fanickel.com

DRILL HOLES AN-25-07 AND AN-25-08 - DETAILED RESULTS

Table 1: Pipestone XL Nickel Alloy Project Summary of Assay Results and DTR Metallurgical Test Results - Drill Hole AN-25-07 and AN-25-08 (RPM Zone)

| Hole ID | From (m) | To (m) | Interval (m) | Mass Pull (%) | Nickel - Magnetic Concentrate Grade Ni ( %) | Nickel - Total Grade Ni (%) | DTR Nickel Grade - Magnetically Recovered Ni (%) | Total Nickel Recovery (%) | Chromium - Magnetic Concentrate Grade Cr (%) | Chromium Total Grade Cr (%) | DTR Chromium Grade - Magnetically Recovered Cr (%) | Cobalt - Magnetic Concentrate Grade Co (%) |

| AN-25-08 | 11 | 491 | 480 | 8.79 | 1.35 | 0.22 | 0.12 | 51.94 | 1.57 | 0.28 | 0.13 | 0.06 |

| including | 158 | 362 | 204 | 8.08 | 1.57 | 0.22 | 0.13 | 58.60 | 1.56 | 0.25 | 0.12 | 0.06 |

| including “Up To” | 12.5 | 2.14 | 0.27 | 0.17 | 83.5 | 9.22 | 3.33 | 0.710 | 0.091 | |||

| AN-25-07 | 9 | 495 | 486 | 9.60 | 0.97 | 0.23 | 0.09 | 40.49 | 1.40 | 0.26 | 0.13 | 0.05 |

| including | 39 | 171 | 132 | 10.23 | 1.06 | 0.23 | 0.11 | 46.23 | 1.28 | 0.25 | 0.13 | 0.05 |

| including “Up To” | 17.20 | 1.71 | 0.29 | 0.13 | 60.9 | 4.15 | 0.83 | 0.51 | 0.08 | |||

Drill Hole AN-25-08 (Section Line S3)

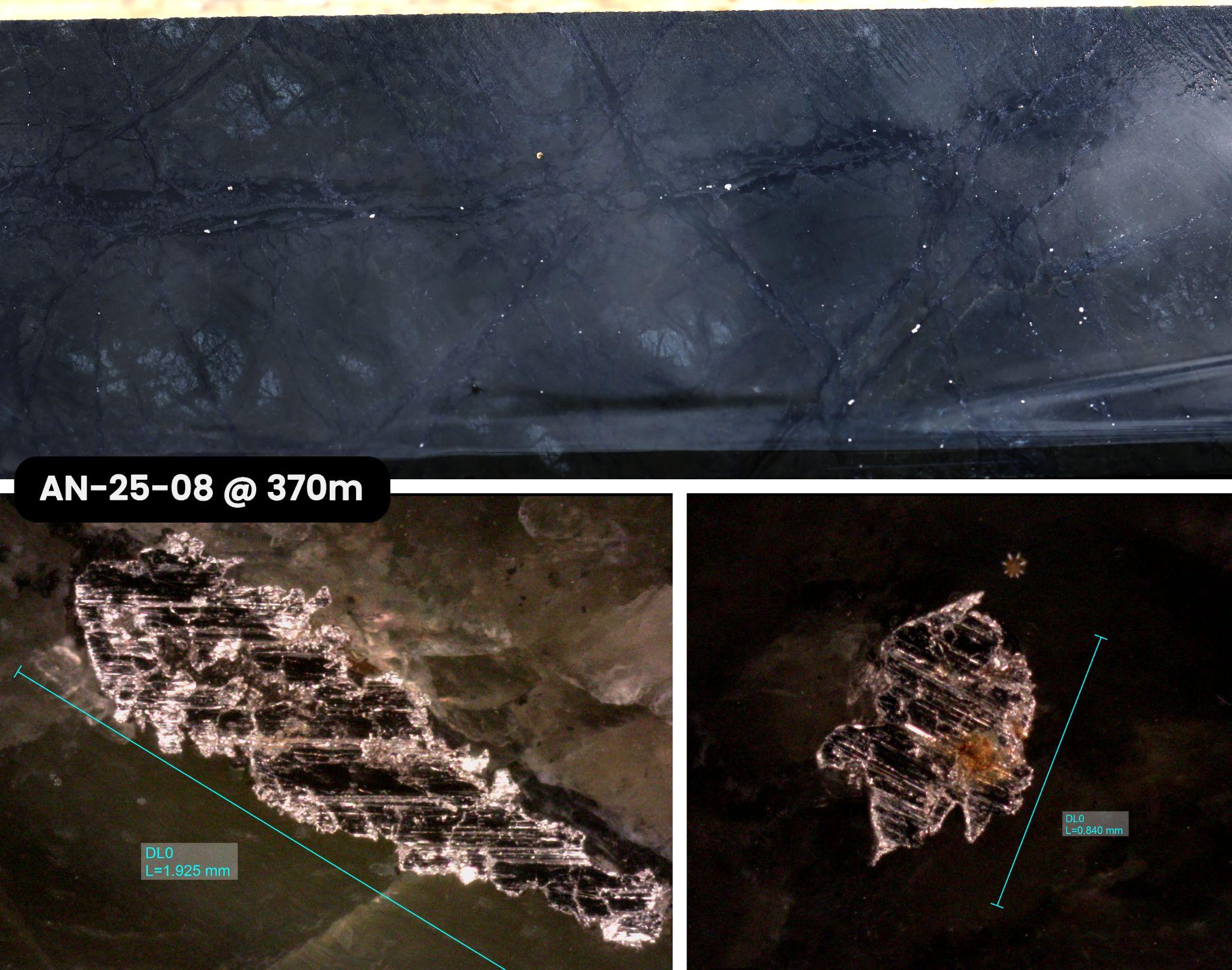

Drill hole AN-25-08 was collared on Section Line S3, approximately 800 meters north of Section S1, and drilled eastward to cross-cut the westward-dipping ultramafic structures. The hole successfully intersected 480 meters of continuous serpentinized peridotite containing visibly disseminated awaruite mineralization from near surface to the end of the hole. DTR testing yielded a magnetic concentrate averaging

The successful results from AN-25-08 doubled the drill-confirmed strike length of the RPM Zone to 800 meters, confirming the continuity of awaruite mineralization within the newly expanded 4-kilometer target area outlined in the October 21, 2025 news release. Phase 2X drilling has now validated approximately

Figure 1: Phase 2X drill plan map at the RPM Zone showing the 800-meter drill-confirmed strike length and the open 10-kilometer strike to Super Gulp within the 30-kilometer Pipestone XL nickel trend.

Figure 2: RPM Zone area map with surface sample DTR nickel results outlining larger target areas within the Pipestone XL Nickel Alloy Project.

Figure 3: Drill core from hole AN-25-08 (370 m) showing disseminated awaruite (nickel-iron-cobalt alloy) in serpentinized peridotite with magnetite veining (top); photomicrographs of awaruite grains up to ~2,000 microns (bottom).

Figure 4: Cross-sectional Line S3 view of the RPM Zone Hole AN-25-08 located 800 meters north of discovery hole AN-24-02. Showing the distribution of magnetic concentrate and DTR nickel values. Including

Drill Hole AN-25-07 (Section Line S2)

Drill hole AN-25-07 was collared on Section Line S2 and drilled westward, oriented down the structural dip prior to refined structural interpretation. Despite the sub-optimal orientation, the hole successfully intersected 486 meters of continuous serpentinized peridotite containing disseminated awaruite mineralization. DTR testing yielded a magnetic concentrate averaging

Geological data from AN-25-07 was instrumental in refining the Company's understanding of the ultramafic body geometry, guiding the optimal orientation of subsequent drill holes, including AN-25-08. The large deformation zone beneath Pipestone Pond, which lies further west, represents a compelling expansion opportunity as outlined in the October 21, 2025 news release. Recent surface sampling from the western shore returned positive DTR results comparable to the RPM Zone, delineating an ~1.8-kilometer-long target area with an expanded target width up to ~1.2 kilometers (compared to ~750 meters currently drill-defined on Section S2). This western expansion area remains untested by drilling and may host significant nickel mineralization due to increased fluid flow promoting serpentinization, a critical process for awaruite formation.

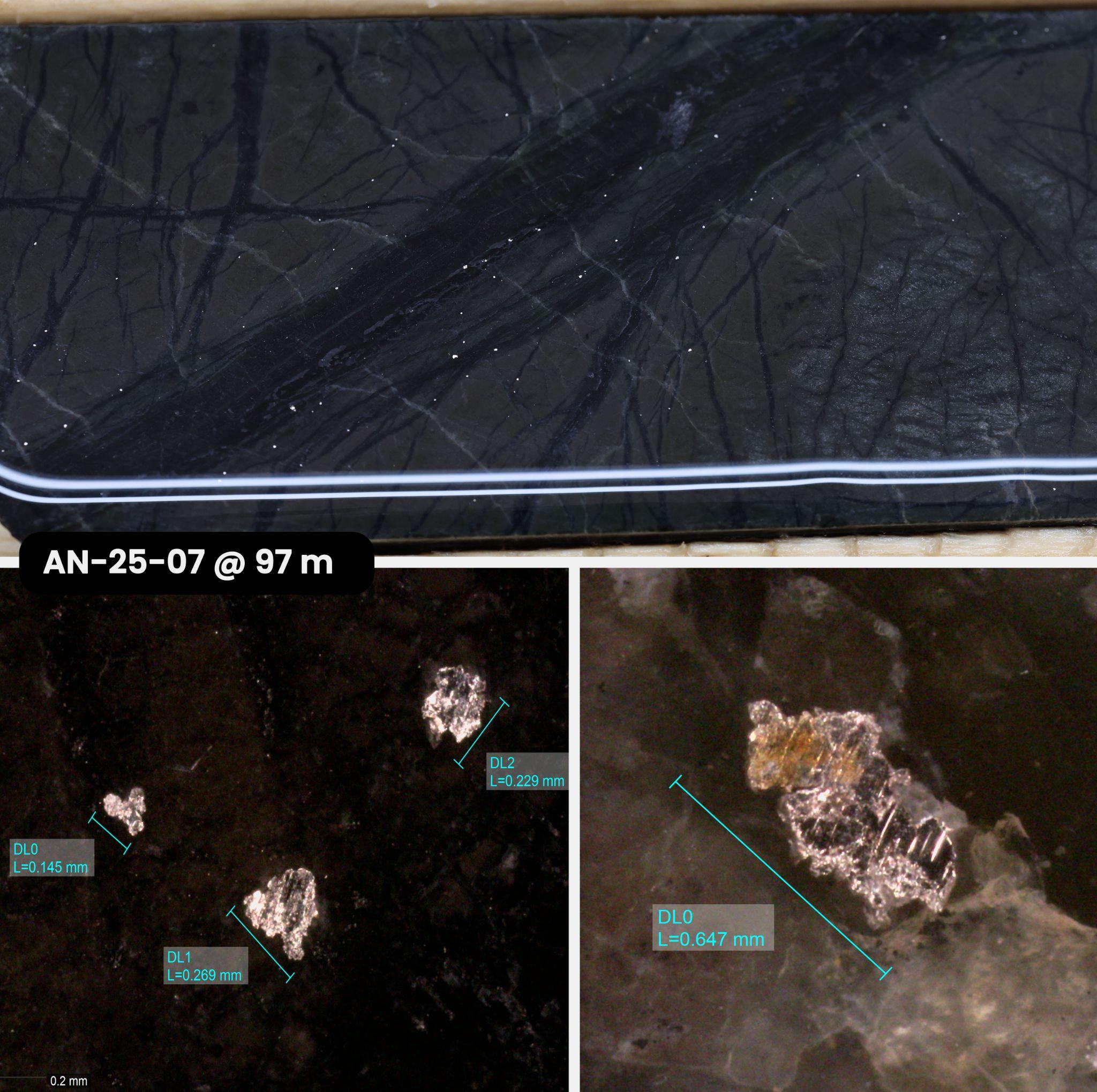

Figure 5: Drill core photograph of hole AN-25-07 at 97 meters showing disseminated awaruite nickel-alloy mineralization (top), with microscope images of awaruite grains up to 647 microns (bottom). Awaruite, a rare, highly magnetic, and ductile nickel-alloy can be seen disseminated within serpentinized ultramafic rocks present over significant areas on the Pipestone XL Nickel Alloy Project.

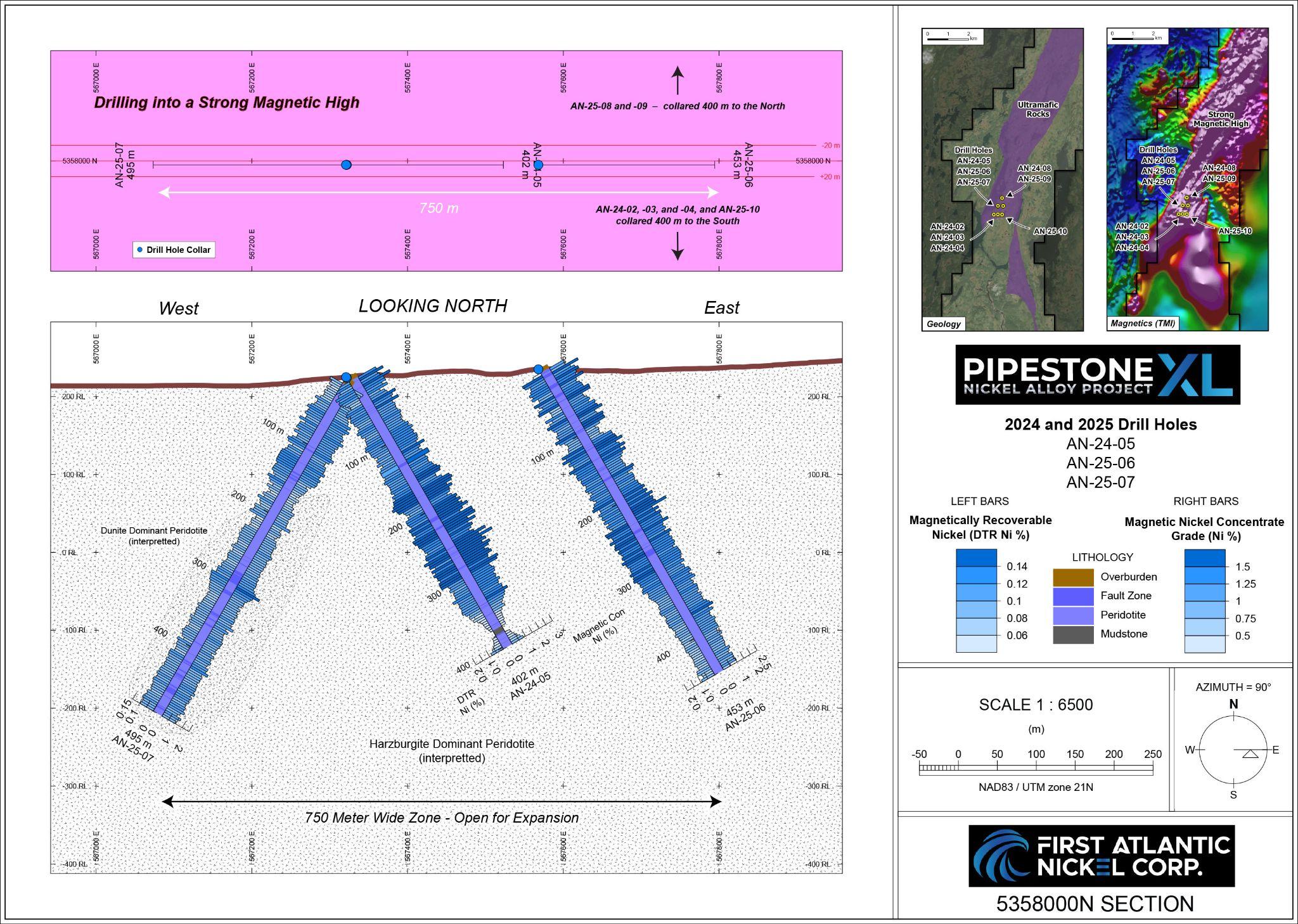

Figure 6: Cross-sectional Line S2 view of the RPM Zone Hole AN-24-05, AN-25-06 & 07 located 400 meters north of discovery hole AN-24-02. Showing the distribution of magnetic concentrate and DTR nickel values.

Table 2: Drill Hole Collar Location Information

| Hole ID | Easting (UTM) | Northing (UTM) | Elevation (m) | Azimuth (°) | Dip (°) | Depth (m) |

| AN-25-08 | 567518 | 5358375 | 219 | 90 | -60 | 491 |

| AN-25-07 | 567321 | 5357995 | 225 | 270 | -60 | 495 |

CHROMIUM AND COBALT - CRITICAL MINERAL BYPRODUCT POTENTIAL

Davis Tube Recovery (DTR) metallurgical testing has demonstrated that both chromium and cobalt are magnetically recovered alongside nickel in the awaruite-bearing magnetic concentrate. Chromium values in the magnetic concentrate have been particularly significant, with grades ranging from

Both chromium and cobalt are designated as critical minerals in the United States and Canada, with essential roles in various industrial applications including stainless steel, metal alloys and rechargeable batteries. The magnetic concentrate produced through DTR testing demonstrates that these critical minerals can be upgraded and concentrated alongside nickel through simple magnetic separation processing.

The Company's ongoing metallurgical development program is investigating the potential to recover chromium and cobalt as byproducts from the magnetic concentration process. The co-recovery of these critical minerals alongside nickel could significantly enhance the strategic value of the Pipestone XL Nickel Alloy Project while developing a domestic North American source of multiple critical minerals that can be sustainably processed onshore, reducing reliance on overseas sources and processing. Further metallurgical test work is planned to optimize the recovery and concentration of these strategically important minerals.

DAVIS TUBE RECOVERY (DTR) METALLURGICAL TEST

The DTR method is a bench scale metallurgical test procedure that provides a measure of magnetically recoverable nickel and is the global, industry standard for geometallurgical testing for magnetic recovery operations and exploration projects. DTR is a laboratory method that uses magnets to separate magnetic and non-magnetic material from a sample, similar to commercial magnetic separators used in mining operations. The percentage of magnetic mass recovered (mass pull) is used together with the assayed nickel grade of the magnetic fraction to calculate the magnetically recoverable nickel.

DTR nickel percentage is calculated by: Mass Pull (%) × Magnetic Nickel Concentrate Grade (%). This represents the portion of nickel that can be recovered through magnetic separation and is not equivalent to a standard whole rock assay result (total nickel). DTR results can vary based on equipment settings and technological advancements. The Company has produced an educational video that breaks down the Davis Tube Recovery test into five simple steps, available at https://www.youtube.com/watch?v=q3zsgDtLWns for those interested in understanding the metallurgical test.

DTR testing serves as a preliminary metallurgical indicator and provides valuable data for process development. The consistent DTR results across the RPM Zone demonstrate the potential for awaruite nickel concentration through magnetic separation, marking a significant initial step toward establishing a smelter-free metallurgical process. This approach could enable production of a high-grade nickel concentrate directly at the mine site, serving as a potential nickel feed into a North American critical minerals supply chain.

AWARUITE - RARE & PURE NATURAL NICKEL-IRON-COBALT ALLOY MINERAL

The sulfur-free nature of awaruite (Ni₃Fe), a naturally occurring nickel-iron-cobalt alloy already in metallic form, eliminates the need for secondary processes such as smelting, roasting or acid leaching that are typical of sulfide or laterite nickel ores. Unlike sulfides, which are not natural alloys, awaruite avoids the challenge of sourcing smelter capacity - a bottleneck in North America's nickel supply chain. With an average nickel grade of ~

Awaruite eliminates the electricity needs, emissions, and environmental impacts associated with conventional smelting, roasting or acid leaching processes of common nickel minerals. Moreover, awaruite's sulfur-free composition removes the risks of acid mine drainage (AMD) and related permitting challenges commonly posed by sulfide minerals. As noted by the United States Geological Survey (USGS) in 2012: "The development of awaruite deposits in other parts of Canada may help alleviate any prolonged shortage of nickel concentrate. Awaruite, a natural iron-nickel alloy, is much easier to concentrate than pentlandite, the principal sulfide of nickel.3"

ABOUT THE RPM ZONE AND PIPESTONE XL NICKEL ALLOY PROJECT

The RPM Zone represents one of multiple discovery zones within First Atlantic's 30-kilometer-long Pipestone XL ultramafic ophiolite trend in central Newfoundland. The zone is characterized by disseminated awaruite mineralization hosted within serpentinized peridotite, with consistent mineralization demonstrated across an 800-meter drill-confirmed strike length that remains open in all directions. The broader 4-kilometer target area identified through surface sampling and geological mapping provides significant expansion potential, with only

The Company's systematic exploration approach, combining detailed geological mapping, surface DTR sampling, and targeted diamond drilling, has successfully outlined a district-scale nickel system with the potential to host multiple large-tonnage awaruite deposits. The RPM Zone's proximity to infrastructure, consistent metallurgical characteristics, and alignment with North American critical mineral objectives position it as a strategic nickel asset for the emerging domestic battery supply chain.

Table 3: Drill Hole Summary of all Reported Drilling at Pipestone XL Project to Date

| Hole ID | From (m) | To (m) | Interval (m) | Mass Pull (%) | Nickel - Magnetic Concentrate Grade Ni ( %) | Nickel - Total Grade Ni (%) | DTR Nickel Grade - Magnetically Recovered Ni (%) | Total Nickel Recovery (%) | Chromium - Magnetic Concentrate Grade Cr (%) | Chromium Total Grade Cr (%) | DTR Chromium Grade - Magnetically Recovered Cr (%) | Cobalt - Magnetic Concentrate Grade Co (%) |

| AN-24-01 | 3.23 | 297 | 293.8 | 6.90 | 0.89 | 0.25 | 0.06 | 24.60 | 1.60 | 0.28 | 0.11 | 0.06 |

| including | 3.23 | 51 | 47.8 | 7.30 | 1.05 | 0.25 | 0.08 | 29.70 | 1.78 | 0.34 | 0.13 | 0.05 |

| including | 51 | 120 | 69 | 6.70 | 0.99 | 0.26 | 0.07 | 25.40 | 1.28 | 0.26 | 0.09 | 0.05 |

| including | 264 | 297 | 33 | 6.50 | 1.17 | 0.23 | 0.08 | 32.60 | 2.00 | 0.31 | 0.13 | 0.07 |

| AN-24-02 | 11 | 394.1 | 383.1 | 9.49 | 1.37 | 0.24 | 0.13 | 52.40 | 1.73 | 0.32 | 0.16 | 0.06 |

| including | 11 | 54 | 43 | 8.30 | 1.42 | 0.24 | 0.12 | 47.90 | 2.30 | 0.33 | 0.19 | 0.06 |

| including | 54 | 105 | 51 | 11.20 | 1.26 | 0.24 | 0.14 | 57.00 | 1.66 | 0.29 | 0.18 | 0.05 |

| including | 105 | 156 | 51 | 8.20 | 1.62 | 0.24 | 0.13 | 54.70 | 1.66 | 0.27 | 0.14 | 0.06 |

| including | 156 | 204 | 48 | 9.10 | 1.35 | 0.22 | 0.12 | 53.20 | 1.88 | 0.31 | 0.17 | 0.06 |

| including | 204 | 261 | 57 | 9.00 | 1.25 | 0.23 | 0.11 | 48.70 | 1.67 | 0.29 | 0.15 | 0.06 |

| including | 261 | 318 | 57 | 10.00 | 1.46 | 0.25 | 0.14 | 56.10 | 1.42 | 0.32 | 0.14 | 0.07 |

| including | 318 | 394.1 | 76.1 | 10.10 | 1.30 | 0.26 | 0.13 | 50.20 | 1.63 | 0.39 | 0.16 | 0.05 |

| AN-24-03 | 18 | 234 | 216 | 9.12 | 1.32 | 0.25 | 0.11 | 44.44 | 1.95 | 0.29 | 0.18 | 0.06 |

| including | 18 | 81 | 63 | 10.04 | 1.05 | 0.25 | 0.10 | 40.24 | 2.15 | 0.31 | 0.20 | 0.05 |

| including | 81 | 180 | 99 | 9.45 | 1.22 | 0.25 | 0.11 | 44.05 | 1.97 | 0.30 | 0.19 | 0.05 |

| including | 180 | 213 | 33 | 7.31 | 1.73 | 0.26 | 0.12 | 46.92 | 1.71 | 0.27 | 0.13 | 0.07 |

| including | 213 | 234 | 21 | 7.63 | 1.93 | 0.27 | 0.15 | 54.95 | 1.57 | 0.26 | 0.12 | 0.07 |

| AN-24-04 | 12 | 378 | 366 | 9.53 | 1.46 | 0.23 | 0.14 | 59.09 | 1.56 | 0.31 | 0.15 | 0.06 |

| including | 12 | 63 | 51 | 9.99 | 1.48 | 0.23 | 0.15 | 62.12 | 1.88 | 0.31 | 0.18 | 0.06 |

| including | 63 | 183 | 120 | 10.03 | 1.27 | 0.22 | 0.13 | 56.66 | 1.70 | 0.32 | 0.17 | 0.06 |

| including | 183 | 255 | 72 | 9.92 | 1.50 | 0.24 | 0.15 | 62.83 | 1.44 | 0.32 | 0.14 | 0.06 |

| including | 255 | 378 | 123 | 8.63 | 1.60 | 0.23 | 0.14 | 58.02 | 1.37 | 0.29 | 0.12 | 0.06 |

| AN-24-05 | 6 | 357 | 351 | 8.21 | 1.47 | 0.24 | 0.12 | 50.26 | 1.53 | 0.29 | 0.12 | 0.06 |

| including | 6 | 207 | 201 | 8.36 | 1.39 | 0.23 | 0.12 | 49.13 | 1.58 | 0.30 | 0.13 | 0.07 |

| including | 207 | 309 | 102 | 7.82 | 1.76 | 0.24 | 0.14 | 56.95 | 1.50 | 0.27 | 0.12 | 0.07 |

| including | 309 | 357 | 48 | 8.32 | 1.18 | 0.24 | 0.10 | 40.59 | 1.39 | 0.29 | 0.11 | 0.05 |

| AN-25-06 | 5.65 | 453 | 447.35 | 9.02 | 1.27 | 0.22 | 0.11 | 51.84 | 1.69 | 0.31 | 0.15 | 0.06 |

| including | 5.65 | 138 | 132.35 | 8.94 | 1.33 | 0.21 | 0.12 | 56.57 | 1.67 | 0.32 | 0.15 | 0.06 |

| including | 138 | 249 | 111 | 9.17 | 1.42 | 0.22 | 0.13 | 57.59 | 1.60 | 0.29 | 0.15 | 0.06 |

| including | 249 | 453 | 204 | 8.92 | 1.18 | 0.23 | 0.11 | 45.92 | 1.70 | 0.30 | 0.15 | 0.06 |

| AN-25-07 | 9 | 495 | 486 | 9.60 | 0.97 | 0.23 | 0.09 | 40.49 | 1.40 | 0.26 | 0.13 | 0.05 |

| including | 39 | 171 | 132 | 10.23 | 1.06 | 0.23 | 0.11 | 46.23 | 1.28 | 0.25 | 0.13 | 0.05 |

| AN-25-08 | 11 | 491 | 480 | 8.79 | 1.35 | 0.22 | 0.12 | 51.94 | 1.57 | 0.28 | 0.13 | 0.06 |

| including | 158 | 362 | 204 | 8.08 | 1.57 | 0.22 | 0.13 | 58.60 | 1.56 | 0.25 | 0.12 | 0.06 |

ABOUT FIRST ATLANTIC NICKEL CORP.

First Atlantic Nickel Corp. (TSXV: FAN) (OTCQB: FANCF) (FSE: P21) is a critical mineral exploration company in Newfoundland & Labrador developing the Pipestone XL Nickel Alloy Project (formerly the Atlantic Nickel Project). The project spans the entire 30-kilometer Pipestone Ophiolite Complex, where multiple zones, including RPM, Super Gulp, Atlantic Lake, and Chrome Pond, contain awaruite (Ni₃Fe), a naturally occurring magnetic nickel-iron-cobalt alloy of approximately ~

The U.S. Geological Survey recognized awaruite's strategic importance in its 2012 Annual Report on Nickel, noting that these deposits may help alleviate prolonged nickel concentrate shortages since the natural alloy is much easier to concentrate than typical nickel sulfides4. The Pipestone XL Nickel Alloy Project is located near existing infrastructure with year-round road access and proximity to hydroelectric power. These features provide favorable logistics for exploration and future development, strengthening First Atlantic’s role to establish a secure and reliable source of North American nickel production for the stainless steel, electric vehicle, aerospace, and defense industries. This mission gained importance when the US added nickel to its critical minerals list in 20225, recognizing it as a non-fuel mineral essential to economic and national security with a supply chain vulnerable to disruption.

INVESTOR INFORMATION

The Company's common shares trade on the TSX Venture Exchange under the symbol "FAN", the American OTCQB Exchange under the symbol “FANCF” and on several German exchanges, including Frankfurt and Tradegate, under the symbol "P21".

Investors can get updates about First Atlantic by signing up to receive news via email and SMS text at www.fanickel.com. Stay connected and learn more by following us on these social media platforms:

https://x.com/FirstAtlanticNi

https://www.facebook.com/fanickelcorp

https://www.linkedin.com/company/firstatlanticnickel/

FOR MORE INFORMATION:

First Atlantic Investor Relations

Robert Guzman

Tel: +1 844 592 6337

rob@fanickel.com

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Disclosure

Adrian Smith, P.Geo., a director and the Chief Executive Officer of the Company is a qualified person as defined by NI 43-101. The qualified person is a member in good standing of the Professional Engineers and Geoscientists Newfoundland and Labrador (PEGNL) and is a registered professional geoscientist (P.Geo.). Mr. Smith has reviewed and approved the technical information disclosed herein.

Analytical Method & QA/QC

Samples were split in half on site, with one half remaining in the core box for future reference and the other half securely packaged for laboratory analysis. The QA/QC protocol included the insertion of blanks, duplicates, and certified reference material (standards), with one QA/QC sample being inserted every 20 samples to monitor the precision and accuracy of the laboratory results. All analytical results successfully passed QA/QC screening at the laboratory, and all Company inserted standards and blanks returned results within acceptable limits.

Samples were submitted to Activation Laboratories Ltd. (“Actlabs”) in Ancaster, Ontario, an ISO 17025 certified and accredited laboratory operating independently of First Atlantic. Each sample was crushed, with a 250 g sub-sample pulverized to

The magnetic fractions are collected, dried, weighed and the magnetic fraction is fused with a lithium metaborate/tetraborate flux and lithium bromide releasing agent and then analyzed on a wavelength dispersive XRF for multiple elements including nickel, cobalt, iron and chromium. The magnetically recovered nickel grade was then calculated by multiplying the XRF fusion nickel value by the weight of the magnetic fraction and dividing by the total recorded feed weight or magnetic mass pulled from the sample.

True widths are currently unknown. However the nickel bearing ultramafic ophiolite and peridotite rocks being targeted and sampled in the Phase 2X drilling program at the Pipestone XL Nickel Alloy Project are mapped on surface and in drilling as several hundred meters to over 1 kilometer wide and approximately 30 kilometers long.

Forward-looking statements:

This news release may include "forward-looking information" under applicable Canadian securities legislation. Such forward-looking information reflects management's current beliefs and are based on a number of estimates and/or assumptions made by and information currently available to the Company that, while considered reasonable, are subject to known and unknown risks, uncertainties, and other factors that may cause the actual results and future events to differ materially from those expressed or implied by such forward-looking information.

Forward-looking information in this news release includes, but is not limited to: statements regarding: the timing, scope and results of the Company’s Phase 1 and Phase 2 work and drilling programs; future project developments; the Company’s objectives, goals, and future plans; statements and estimates of market conditions; the viability of magnetic separation as a low-impact processing method for awaruite; the strategic and economic implications of the Company’s projects; and expectations regarding future developments and strategic plans; Readers are cautioned that such forward-looking information are neither promises nor guarantees and are subject to known and unknown risks and uncertainties including, but not limited to, general business, economic, competitive, political and social uncertainties, uncertain and volatile equity and capital markets, lack of available capital, actual results of exploration activities, environmental risks, future prices of base and other metals, operating risks, accidents, labour issues, delays in obtaining governmental approvals and permits, and other risks in the mining and clean energy industries. Additional factors and risks including various risk factors discussed in the Company’s disclosure documents which can be found under the Company’s profile on http://www.sedarplus.ca. Should one or more of these risks or uncertainties materialize, or should assumptions underlying the forward-looking statements prove incorrect, actual results may vary materially from those described herein as intended, planned, anticipated, believed, estimated or expected.

The Company is presently an exploration stage company. Exploration is highly speculative in nature, involves many risks, requires substantial expenditures, and may not result in the discovery of mineral deposits that can be mined profitably. Furthermore, the Company currently has no mineral reserves on any of its properties. As a result, there can be no assurance that such forward-looking statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. The Company undertakes no obligation to update forward-looking information, except as required by applicable securities laws.

_______________________________________

1 https://www.sciencedirect.com/science/article/abs/pii/S0892687522002667

2 https://fpxnickel.com/projects-overview/what-is-awaruite/

3 https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/mineral-pubs/nickel/mcs-2012-nicke.pdf

4 https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/mineral-pubs/nickel/mcs-2012-nicke.pdf

5 https://www.usgs.gov/news/national-news-release/us-geological-survey-releases-2022-list-critical-minerals

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/82d26e6b-e06b-4b23-808c-a6ade65ecfdc

https://www.globenewswire.com/NewsRoom/AttachmentNg/454973a6-4488-4559-bb0f-a8f7174c1766

https://www.globenewswire.com/NewsRoom/AttachmentNg/7eb1c47e-a894-4d8b-bb6b-e7260c83b1ae

https://www.globenewswire.com/NewsRoom/AttachmentNg/928f9a53-b65f-4245-b343-949ef778d016

https://www.globenewswire.com/NewsRoom/AttachmentNg/7652adc7-2df6-4cf0-8c1f-62fa08d9eea6

https://www.globenewswire.com/NewsRoom/AttachmentNg/337b2f72-867c-48c4-a459-175241e879ec