PyroGenesis Confirms Production of Fumed Silica at Pilot Scale Following Independent Analysis

Rhea-AI Summary

Positive

- Successfully produced and validated fumed silica at pilot scale

- Material yield exceeded expectations, suggesting favorable project economics

- Product quality comparable to commercial-grade fumed silica (Evonik)

- Impurities are in removable state as anticipated

Negative

- Project still requires further optimization and validation steps

- No guarantee of ultimate success as stated by CEO

- Commercial viability yet to be proven

News Market Reaction

On the day this news was published, PYRGF gained 5.83%, reflecting a notable positive market reaction.

Data tracked by StockTitan Argus on the day of publication.

Yield of Fumed Silica Material Exceeds Expectations in Latest Pilot Runs

MONTREAL, May 21, 2025 (GLOBE NEWSWIRE) -- PyroGenesis Inc. (“PyroGenesis”) (http://pyrogenesis.com) (TSX: PYR) (OTCQX: PYRGF) (FRA: 8PY1), a high-tech company that designs, develops, manufactures and commercializes all-electric plasma processes and sustainable solutions to support heavy industry in their energy transition, emission reduction, commodity security, and waste remediation efforts, announces today further to its news release dated May 15, 2025, and today’s press release from the Company’s client HPQ Silicon Inc. (“HPQ”), independent analysis of material produced during the latest phase of system testing of the Fumed Silica Reactor (the “FSR”) is in fact fumed silica. PyroGenesis is engaged to develop the Fumed Silica Reactor by HPQ Silica Polvere Inc. (“Polvere”), a subsidiary of HPQ.

As previously announced, the new PyroGenesis designed FSR pilot plant has progressed through several important stages. After successfully proving out the underlying assumptions using lab scale tests, PyroGenesis is now testing the assumptions at pilot plant scale, with the current focus on validating equipment scale-up from lab to pilot plant scale and replicating the lab-scale fumed silica product quality.

PyroGenesis recently announced that (i) an important milestone of producing and collecting powder in the product recovery unit known as the “baghouse” had been achieved, and (ii) samples had been sent to an independent laboratory to confirm that (a) the powder collected was fumed silica, and (b) what was collected was what was expected, and that any impurities that are observed were not only anticipated but are in a state that was expected and which can be removed.

The announcement today confirms that an independent analysis of the powder reflects that:

(1) the powder collected from the baghouse is in fact fumed silica,

(2) any impurities observed were not only anticipated but are in a state that was expected and which can be removed, and

(3) the amount produced was greater than anticipated and as such bodes well for the ultimate economics of the project.

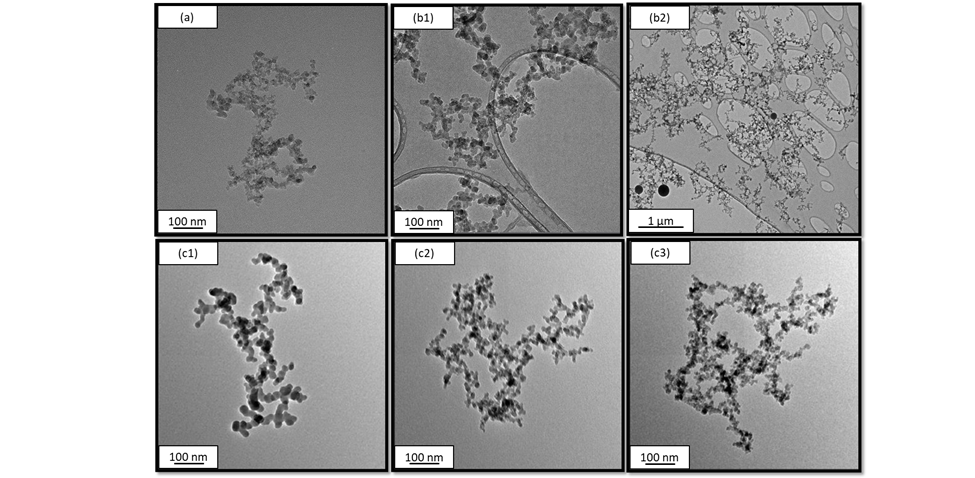

Figure 1. TEM images of fumed silica nanoparticles, (a) Lab-Scale Silica Polvere collected from inside the Reactor (b1-b2) Pilot-Scale Silica Polvere collected from the Baghouse and (c1) Evonik Commercial Grade Aerosil 90, (c2) Evonik Commercial Grade Aerosil 150, (c3) Evonik Commercial Grade Aerosil 200

In a side-by-side comparison, the PyroGenesis material appears well aligned with the microstructure and complexity of mid to high surface area of commercial grade fumed silica produced by Evonik Corporation, typically in the range of 150 to 200 m²/g.

The balance of the pilot plant program will now be focused on two primary objectives:

a) first, to focus on enhancing product purity by perfecting powder morphology and viscosity, and

b) second, to focus on delivering the production target goal of 50 tonnes per year (TPY).

In parallel, the FSR pilot plant will undergo a series of optimization tests, which aim to:

- Improve process control and parameter stability,

- Increase silica conversion efficiency and yield, and

- Increase product surface areas.

These efforts will provide invaluable information required for scale-up plans and equipment modifications required to make the system commercially viable. Together, the results of the characterization and optimization phases will essentially determine market fit.

“Today’s announcement is a welcomed milestone which has increased the probability of success, but we must remember that until we have proven out every step, there is no guarantee that success will be the result,” said P. Peter Pascali, President and CEO of PyroGenesis, “Having said that we are very pleased with the results of this analysis, as it confirms our theoretical expectations at a key juncture in the overall project.”

Fumed silica is one of the most widely used industrial materials, and can be found in thousands of products we use every day, including personal care, cosmetics, toothpaste, pet litter, powdered food, milkshakes, instant coffee, pharmaceuticals, agriculture (food & feed), adhesives, paints, inks, photocopy toner, sealants, fiber optic cables, thermal insulation, construction materials, and batteries, just to name a few. It is often used in these products as a thickening/anti-caking agent, used to stabilize and improve the texture and consistency of the end-product.

PyroGenesis’ involvement in developing fumed silica from quartz is part of its three-vertical solution ecosystem that aligns with economic drivers that are key to global heavy industry. Fumed powders are part of PyroGenesis’ Commodity Security and Optimization vertical, where the development of advanced material production techniques, and the use of technology such as plasma to recover viable metals, chemicals, and minerals from industrial waste, helps to maximize raw materials and improve the availability of critical minerals. The Company’s other verticals are Energy Transition and Emission Reduction and Waste Remediation.

About PyroGenesis Inc.

PyroGenesis, a high-tech company, is a proud leader in the design, development, manufacture and commercialization of advanced plasma processes and sustainable solutions which reduce greenhouse gases (GHG) and are economically attractive alternatives to conventional “dirty” processes. PyroGenesis has created proprietary, patented and advanced plasma technologies that are being vetted and adopted by multiple multibillion dollar industry leaders in four massive markets: iron ore pelletization, aluminum, waste management, and additive manufacturing. With a team of experienced engineers, scientists and technicians working out of its Montreal office, and its 3,800 m2 and 2,940 m2 manufacturing facilities, PyroGenesis maintains its competitive advantage by remaining at the forefront of technology development and commercialization. The operations are ISO 9001:2015 and AS9100D certified, having been ISO certified since 1997. PyroGenesis’ shares are publicly traded on the TSX in Canada (TSX: PYR), the OTCQX in the US (OTCQX: PYRGF), and the Frankfurt Stock Exchange in Germany (FRA: 8PY1).

Cautionary and Forward-Looking Statements

This press release contains “forward-looking information” and “forward-looking statements” (collectively, “forward-looking statements”) within the meaning of applicable securities laws. In some cases, but not necessarily in all cases, forward-looking statements can be identified by the use of forward-looking terminology such as “plans”, “targets”, “expects” or “does not expect”, “is expected”, “an opportunity exists”, “is positioned”, “estimates”, “intends”, “assumes”, “anticipates” or “does not anticipate” or “believes”, or variations of such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “might”, “will” or “will be taken”, “occur” or “be achieved”. In addition, any statements that refer to expectations, projections or other characterizations of future events or circumstances contain forward-looking statements. Forward-looking statements are not historical facts, nor guarantees or assurances of future performance but instead represent management’s current beliefs, expectations, estimates and projections regarding future events and operating performance.

Forward-looking statements are necessarily based on a number of opinions, assumptions and estimates that, while considered reasonable by PyroGenesis as of the date of this release, are subject to inherent uncertainties, risks and changes in circumstances that may differ materially from those contemplated by the forward-looking statements. Important factors that could cause actual results to differ, possibly materially, from those indicated by the forward-looking statements include, but are not limited to, the risk factors identified under “Risk Factors” in PyroGenesis’ latest annual information form, and in other periodic filings that it has made and may make in the future with the securities commissions or similar regulatory authorities, all of which are available under PyroGenesis’ profile on SEDAR+ at www.sedarplus.ca. These factors are not intended to represent a complete list of the factors that could affect PyroGenesis. However, such risk factors should be considered carefully. There can be no assurance that such estimates and assumptions will prove to be correct. You should not place undue reliance on forward-looking statements, which speak only as of the date of this release. PyroGenesis undertakes no obligation to publicly update or revise any forward-looking statement, except as required by applicable securities laws.

Neither the Toronto Stock Exchange, its Regulation Services Provider (as that term is defined in the policies of the Toronto Stock Exchange) nor the OTCQX Best Market accepts responsibility for the adequacy or accuracy of this press release.

For further information please contact:

Rodayna Kafal, Vice President, IR/Comms. and Strategic BD

E-mail: ir@pyrogenesis.com

http://www.pyrogenesis.com

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/d39e72b6-407d-4dd5-b640-3345071eceeb