PyroGenesis Signs Additional Contract with Constellium to Advance Aluminum Furnace Electrification Using Plasma Torch Technology

Rhea-AI Summary

PyroGenesis (OTCQX: PYRGF) has secured a new contract with Constellium to implement plasma torch technology in aluminum remelting furnaces, marking Phase 2 of their collaboration agreement from April 2024. The project aims to advance industrial-scale deployment of electrification in the aluminum sector.

The implementation phase includes installing PyroGenesis' proprietary plasma technology in a demonstrator furnace at a Constellium casthouse, with commissioning expected by Q1 2026. This initiative supports Constellium's decarbonization strategy and addresses the aluminum industry's need to reduce emissions by 24% by 2030 and 92% by 2050 compared to 2021 levels.

The project is particularly significant as global aluminum demand is projected to increase by 40% by 2030 and up to 80% by 2050, driven by growth in automotive, aerospace, and packaging sectors.

Positive

- None.

Negative

- Financial terms of the contract remain confidential, limiting assessment of economic impact

- Extended timeline with commissioning not expected until Q1 2026

- Technology still in demonstration phase, pending industrial-scale validation

News Market Reaction

On the day this news was published, PYRGF declined 1.51%, reflecting a mild negative market reaction.

Data tracked by StockTitan Argus on the day of publication.

Marks next phase of industrial-scale deployment for aluminum sector energy transition.

MONTREAL, Aug. 05, 2025 (GLOBE NEWSWIRE) -- PyroGenesis Inc. (“PyroGenesis”) (http://pyrogenesis.com) (TSX: PYR) (OTCQX: PYRGF) (FRA: 8PY1), a high-tech company that designs, develops, manufactures and commercializes advanced all-electric plasma processes and sustainable solutions to support heavy industry in their energy transition, emission reduction, commodity security, and waste remediation efforts, announces that it has signed an additional contract with Constellium, one of the world’s largest aluminum transformation and recycling companies, for the purchase of plasma torch technology and related peripheral components to be implemented in an aluminum remelting furnace as part of a broader decarbonization effort. The financial terms of the contract will remain confidential. This contract marks the launch of Phase 2 of the project – industrial implementation – as part of the two companies’ collaboration agreement of April 2024. The collaborative agreement outlined Constellium’s stated plan to use PyroGenesis plasma torches and associated processes as potential replacement heating sources for aluminum remelting furnaces in Constellium’s aluminum cast houses.

PROJECT HIGHLIGHTS

Purpose: explore PyroGenesis’ all-electric plasma torches, among other alternative technologies, to implement cleaner, more sustainable methods for high-temperature industrial heating, reducing carbon emissions and enhancing energy efficiency in aluminum processing

Scope: integration of proprietary plasma technology in a demonstrator furnace at a Constellium casthouse

Timeline: commissioning expected by Q1 2026

Strategic Impact: supports Constellium’s roadmap to reduce GHG emissions

As previously reported (PyroGenesis’ April 10, 2024, news release), PyroGenesis and Constellium signed a letter of intent to implement a demonstrator plasma-heated furnace in one of Constellium’s casthouses, as part of their decarbonization strategy. The initial project was to be implemented in two phases, the first of which corresponded to an engineering and feasibility study. The second phase, aiming at industrial execution, has now begun with the signing of this plasma torch contract. This project phase is estimated to be completed by Q1 2026.

“The aluminum industry represents a significant growth area for PyroGenesis, supported by market leaders like Constellium – companies that are embracing innovation and responding positively to our engineering expertise and industry-leading technology,” said Mr. P. Peter Pascali, President and CEO of PyroGenesis. “Streamlining energy use by electrifying more processes across industrial operations only makes sense when quality and economics remain intact, as is the case with PyroGenesis’ plasma torches. Constellium is demonstrating bold leadership in embracing cleaner, more efficient energy pathways. Together, we’re taking a major step toward electrifying an energy-intensive segment of aluminum manufacturing.”

“We are pleased to take this next step with PyroGenesis to advance the maturity of plasma torch technology for aluminum remelting,” said Ludovic Piquier, Senior VP, Manufacturing Excellence and Chief Technical Officer of Constellium. “This collaboration reflects our commitment to decarbonizing our operations through innovative, sustainable solutions.”

Image 1: reverberatory melting furnace in use at one of Constellium’s aluminum facilities.

INDUSTRY AND MARKET CONTEXT

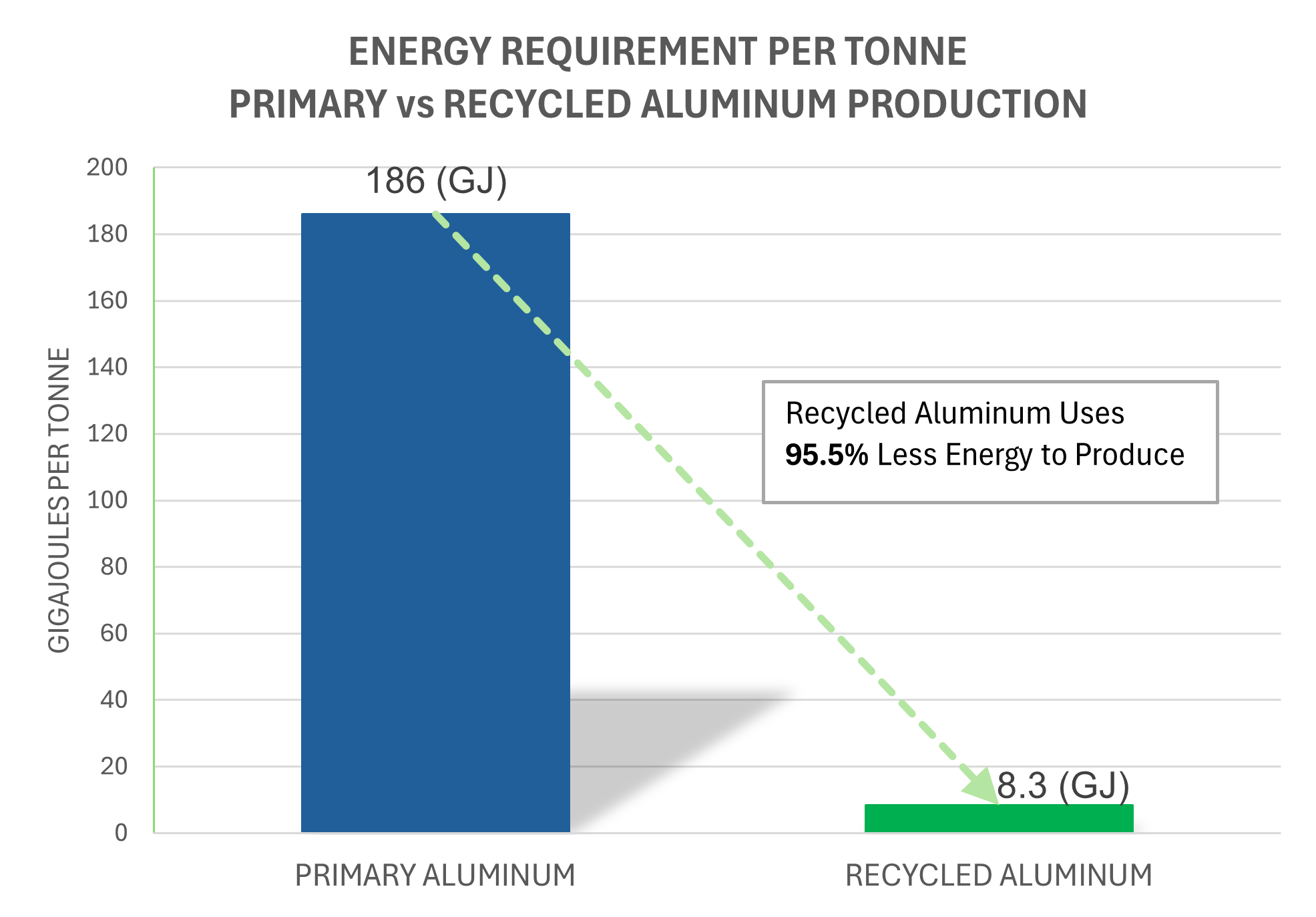

- Primary aluminum production is an energy intensive process that is typically produced using electricity; secondary aluminum production, using recycled aluminum, requires

95% less energy to produce. i - According to Pathways to Decarbonization: A North American Aluminum Roadmap, aluminum production emissions must decline by

24% by 2030,63% by 2040, and92% by 2050 compared to 2021 levels to meet net-zero targets, highlighting the urgent need for cleaner technologies across both primary production and secondary remelting. ii - Aspects of secondary aluminum production that use fossil fuels (natural gas, etc.), such as the remelting of scrap metal, can potentially utilize alternative energy sources such as plasma.

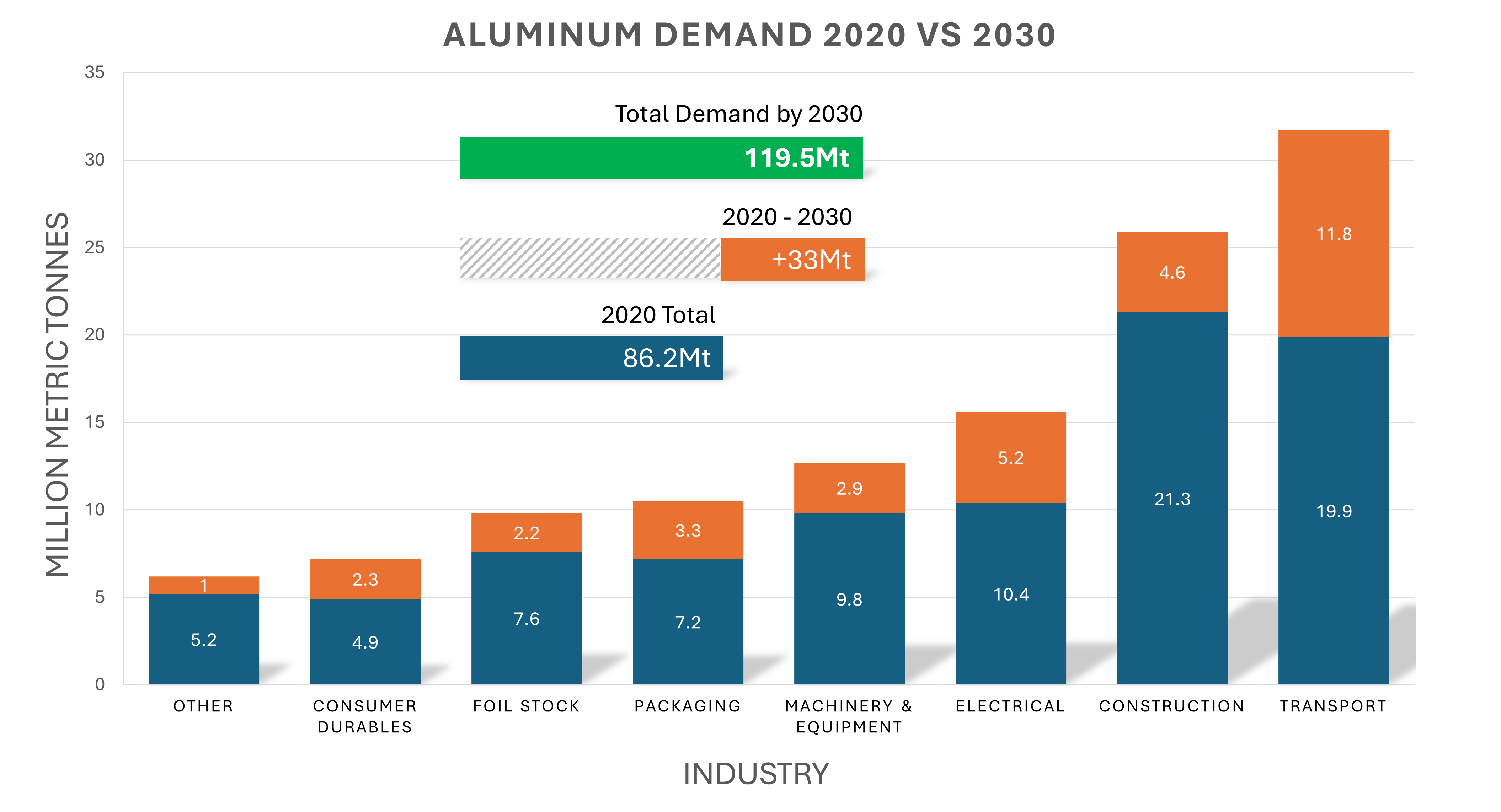

- Global aluminum demand is projected to rise nearly

40% by 2030 and up to80% by 2050, driven by growth in automotive, aerospace, and packaging. iii iv - Plasma-based electrification offers a cleaner, scalable alternative to traditional fuel-based heating, aligning with energy transition and decarbonization mandates.

Image 2: secondary aluminum production from recycled metal uses up to

Image 3: growing aluminum demand across various industries shows aluminum demand expected to increase

PyroGenesis’ development of plasma torches for use in high temperature industrial furnaces is part of the Company’s three-tiered solution ecosystem that aligns with economic drivers that are key to global heavy industry. Plasma torches for aluminum melting furnaces are part of the Company’s Energy Transition & Emissions Reduction tier, where fuel switching utilizing the Company’s electric-powered plasma torches helps heavy industry reduce greenhouse gas emissions and fossil fuel use. The other tiers are Waste Remediation, and Commodity Security and Optimization.

About PyroGenesis Inc.

PyroGenesis, a high-tech company, is a proud leader in the design, development, manufacture and commercialization of advanced plasma processes and sustainable solutions which reduce greenhouse gases (GHG) and are economically attractive alternatives to conventional “dirty” processes. PyroGenesis has created proprietary, patented and advanced plasma technologies that are being vetted and adopted by multiple multibillion dollar industry leaders in four massive markets: iron ore pelletization, aluminum, waste management, and additive manufacturing. With a team of experienced engineers, scientists and technicians working out of its Montreal office, and its 3,800 m2 and 2,940 m2 manufacturing facilities, PyroGenesis maintains its competitive advantage by remaining at the forefront of technology development and commercialization. The operations are ISO 9001:2015 and AS9100D certified, having been ISO certified since 1997. PyroGenesis’ shares are publicly traded on the TSX in Canada (TSX: PYR), the OTCQX in the US (OTCQX: PYRGF), and the Frankfurt Stock Exchange in Germany (FRA: 8PY1).

Cautionary and Forward-Looking Statements

This press release contains “forward-looking information” and “forward-looking statements” (collectively, “forward-looking statements”) within the meaning of applicable securities laws. In some cases, but not necessarily in all cases, forward-looking statements can be identified by the use of forward-looking terminology such as “plans”, “targets”, “expects” or “does not expect”, “is expected”, “an opportunity exists”, “is positioned”, “estimates”, “intends”, “assumes”, “anticipates” or “does not anticipate” or “believes”, or variations of such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “might”, “will” or “will be taken”, “occur” or “be achieved”. In addition, any statements that refer to expectations, projections or other characterizations of future events or circumstances contain forward-looking statements. Forward-looking statements are not historical facts, nor guarantees or assurances of future performance but instead represent management’s current beliefs, expectations, estimates and projections regarding future events and operating performance.

Forward-looking statements are necessarily based on a number of opinions, assumptions and estimates that, while considered reasonable by PyroGenesis as of the date of this release, are subject to inherent uncertainties, risks and changes in circumstances that may differ materially from those contemplated by the forward-looking statements. Important factors that could cause actual results to differ, possibly materially, from those indicated by the forward-looking statements include, but are not limited to, the risk factors identified under “Risk Factors” in PyroGenesis’ latest annual information form, and in other periodic filings that it has made and may make in the future with the securities commissions or similar regulatory authorities, all of which are available under PyroGenesis’ profile on SEDAR+ at www.sedarplus.ca. These factors are not intended to represent a complete list of the factors that could affect PyroGenesis. However, such risk factors should be considered carefully. There can be no assurance that such estimates and assumptions will prove to be correct. You should not place undue reliance on forward-looking statements, which speak only as of the date of this release. PyroGenesis undertakes no obligation to publicly update or revise any forward-looking statement, except as required by applicable securities laws.

Neither the Toronto Stock Exchange, its Regulation Services Provider (as that term is defined in the policies of the Toronto Stock Exchange) nor the OTCQX Best Market accepts responsibility for the adequacy or accuracy of this press release.

For further information please contact:

Rodayna Kafal, Vice President, IR/Comms. and Strategic BD

E-mail: ir@pyrogenesis.com

http://www.pyrogenesis.com

ii https://www.aluminum.org/Decarb

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/cae86741-7f59-4f40-96db-f1876a82a6e9

https://www.globenewswire.com/NewsRoom/AttachmentNg/c43829b7-9b93-4022-b110-de9102d39f62

https://www.globenewswire.com/NewsRoom/AttachmentNg/3090f5b9-4977-47e1-9e6d-5b7c9313aaa1