Volt Carbon Consolidates Operations to Guelph, Commences Mobile Graphite Processing Development, and Provides Update on Capabilities, IP, and Battery Testing

Rhea-AI Summary

Volt Carbon Technologies (OTCQB: TORVF) has consolidated all operations to its Guelph, Ontario facility, marking a strategic shift to accelerate commercialization of its patented mobile graphite purification technology. The company has completed over 500 process trials on 4 tonnes of graphitic rock and stockpiled 40 tonnes of graphitic rock for upcoming pilot-scale production.

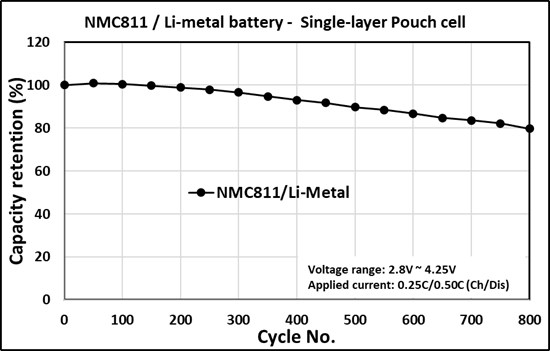

Key technological achievements include: 1,100 charge-discharge cycles with 80% capacity retention in proprietary LFP batteries, and 800 cycles with 80% capacity retention at 400 Wh/kg in lithium-metal batteries with NMC811 cathodes. The Guelph facility now supports testing of 160 coin cells and 168 pouch cells, with new capabilities including a -70°C environmental chamber for aerospace and defense applications.

The company has expanded its IP portfolio with new U.S. and Canadian patents for its metal-organic framework electrolyte used in lithium-metal batteries.

Positive

- Achieved 1,100 charge-discharge cycles with 80% capacity retention in LFP batteries

- Lithium-metal battery reached 800 cycles with 80% capacity retention at 400 Wh/kg energy density

- Quadrupled battery test capacity at Guelph facility since 2020

- Secured new U.S. and Canadian patents for metal-organic framework electrolyte

- Successfully completed over 500 process trials on graphite purification

- Stockpiled 40 tonnes of graphitic rock for pilot-scale production

Negative

- Decommissioning of Scarborough site requires operational adjustment

- High-nickel NMC/lithium-metal technology still needs optimization to reach 1,000 cycles target

News Market Reaction

On the day this news was published, TORVF gained 31.13%, reflecting a significant positive market reaction.

Data tracked by StockTitan Argus on the day of publication.

Calgary, Alberta--(Newsfile Corp. - July 16, 2025) - Volt Carbon Technologies Inc. (TSXV: VCT) (OTCQB: TORVF) ("Volt Carbon" or the "Company") is pleased to announce the consolidation of all operations to its Guelph, Ontario facility as of July 15, 2025, and the decommissioning of its Scarborough site. This strategic realignment streamlines operations and accelerates the commercialization of Volt Carbon's patented mobile graphite purification technology while advancing its high-performance battery initiatives.

As part of this transition, Volt Carbon has centralized all graphite processing, customer trials, and equipment fabrication activities to the Guelph facility. This enables the Company to scale production of its mobile purification units and streamline its research and development efforts. Over 500 process trials were conducted at the Scarborough facility on 4 tonnes of graphitic rock to optimize Volt Carbon's dry separation process. Approximately 50 kilograms of purified large flake graphite are now stored in Guelph, ready for anode and graphene trials. Using this material, the Guelph plant is actively producing small batches of expandable graphite, graphite foils, and graphene for customer evaluation and development programs.

Two bench-model air classifier units have been fabricated for mobile deployment, with the second unit recently completed and prepared for installation in sea containers. All future graphite purification will be conducted using Volt Carbon's patented dry separation technology housed in these modular, containerized systems. This mobile approach supports near-source processing at mine sites and project locations, reducing environmental impact and transportation costs. The Company is also preparing a second batch of graphite for "Green Anode" fabrication with Charge CCCV (C4V), using Volt Carbon's purified material.

Facility Update

To support commercialization, Volt Carbon has stockpiled a bulk sample of 40 tonnes of graphitic rock at its Guelph site, with grades ranging from 8

IP Update

Volt Carbon has also expanded its intellectual property portfolio. In addition to the prior news (Dec 2024) announcing the grant of U.S. Patent No. 12172192 for its dry air classification system, the Company has been granted US Patent 12341150B2 and Canadian Patent No. 3134407 for its metal-organic framework (MOF) electrolyte used in lithium-metal battery applications.

Battery Advancements

Further to its last update on May 8, 2024, Volt Carbon has achieved 1,100 charge-discharge cycles with

Separately, Volt Carbon's lithium-metal battery featuring high-nickel NMC811 cathodes has achieved 800 cycles with

Figure. 1: NMC811/Li-Metal pouch cell, Cycle data, 2.8-4.25V, 0.25C/0.5C (Ch/Dis), 25 °C

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/9904/258993_52fa8e55a4277926_001full.jpg

Volt Carbon will continue to optimize its high-nickel NMC/lithium-metal technology, with the goal of achieving 1,000 cycles with

"Our continued investment in people, equipment, and capability—combined with a relentless focus on results—positions Volt Carbon for long-term success," said V-Bond Lee, CEO. "The transition to mobile purification gives us a scalable, decentralized solution for critical minerals, while our battery team continues to push performance boundaries. We are building the infrastructure to support the future of energy and mobility."

Volt Carbon Technologies, headquartered in Calgary, is a publicly traded carbon science company focused on energy storage and green energy solutions. The company operates a lithium-ion battery plant and a graphite processing facility in Guelph Ontario. Volt Carbon also holds mining claims across Ontario, Quebec, and British Columbia, supporting its commitment to sustainable resource development. For the latest updates on Volt Carbon's projects and news, visit www.voltcarbontech.com.

On behalf of the Board of Directors,

Volt Carbon Technologies Inc.

V-Bond Lee, P. Eng.

CEO, President, Chairman of the Board and Director

Information Contact :

Email: info@voltcarbontech.com

Tel: (519-763-1197)

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

FORWARD-LOOKING STATEMENTS AND FUTURE ORIENTED FINANCIAL INFORMATION: This press release contains forward-looking statements and future oriented financial information, within the meaning of applicable securities legislation, concerning Volt Carbon's business and affairs. In certain cases, forward-looking statements or future oriented financial information can be identified by the use of words such as "plans", "expects" or "does not expect", "intends" "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might" or "will be taken", "occur" or "be achieved". Such statements and information include, but are not limited to: (1) the expected benefits of consolidating operations in Guelph and decommissioning the Scarborough facility; (2) the scalability, commercialization, and on-site deployment potential of Volt Carbon's mobile graphite purification technology; (3) the anticipated use of graphitic rock for use in upcoming pilot-scale production campaigns; (4) the advancement, testing, and performance targets of Volt Carbon's Solid UltraBattery division, including energy density, cycle life, and scaling plans; (5) the expected outcomes of pilot-scale processing campaigns using bulk graphite samples; (6) the development and potential applications of expandable graphite, graphene, and graphite foils; (7) the usefulness and reliability of newly added lab infrastructure and expanded testing capabilities; (8) the impact of granted patents, including U.S. Patent No. 12,172,192 and Canadian Patent No. 3,134,407, on Volt Carbon's competitive positioning and commercialization efforts; (9) the Company's goal of achieving 1,000 cycles with

Statements of past performance should not be construed as an indication of future performance. Forward-looking statements and future oriented financial information involve significant risks, uncertainties, and assumptions, and should not be read as guarantees of future performance or results and will not necessarily be accurate indications of whether or not such results will be achieved. These assumptions and risks include, but are not limited to: the continued existence of the carbon credit program in Canada and future viability of same, regulatory and governmental changes, capital and operating costs varying significantly from estimates, the ability to replicate the results of the Study in a demonstrator unit and at a commercial production level, the ability to construct a demonstrator unit with reasonable construction and operating costs, the ability to construct units that can operate on a commercial scale, the data available at the time of the Study, the reliability of third-party sources, including the Study, the assumptions and limitations outlined in the Study, the preliminary in nature of the Study and the fact that estimates provided therein are subject to revisions in subsequent design phases or through more comprehensive assessments such as a Feasibility Study or Life Cycle Assessment. A number of factors, including those discussed above, could cause actual results to differ materially from the results discussed in the forward-looking statements. Any and all such forward-looking statements or future oriented financial information in this press release are expressly qualified in their entirety by these cautionary statements. Readers are cautioned not to place undue reliance on such forward-looking statements and future oriented financial information. Forward-looking information and future oriented financial information are provided as of the date of this press release, and Volt Carbon assumes no obligation to update or revise them to reflect new events or circumstances, except as may be required under applicable securities legislation.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/258993