Ucore Enters into Strategic Partnership with Metallium Limited

Rhea-AI Summary

Ucore Rare Metals (OTCQX:UURAF) has formed a strategic partnership with Metallium Limited to enhance rare earth processing capabilities. The 12-month collaboration integrates Metallium's Flash Joule Heating (FJH) technology with Ucore's RapidSX separation platform at their US DoW-backed Louisiana refinery.

The partnership will develop a two-stage program: First, bench-scale testing of rare earth concentrate processing and magnet scrap conversion; second, pilot-scale production of mixed REE chlorides at Ucore's Commercial Demonstration Plant in Kingston, Ontario. The integrated system aims to process various feedstocks, including conventional REE concentrates, magnet scrap, e-waste, and lighting waste, producing separated rare earth oxides like NdPr, Dy, and Tb.

Positive

- None.

Negative

- Agreement is only for 12 months with no guaranteed commercial arrangement

- No immediate revenue generation or financial terms disclosed

- Technology integration still requires testing and validation through multiple stages

News Market Reaction

On the day this news was published, UURAF gained 3.53%, reflecting a moderate positive market reaction.

Data tracked by StockTitan Argus on the day of publication.

Ucore Announces:

- The formation of a strategic partnership with Metallium Limited which will add to potential feedstock sources for the Company's US DoW backed rare earth refinery in Alexandria, Louisiana.

- Metallium's Flash Joule Heating process provides an alternative to traditional sulfate leaching approaches to generating mixed rare earth products which will be suitable for refining using Ucore's RapidSXTM technology.

- A staged program is being developed combining Metallium's front-end upgrading capability with Ucore's downstream RapidSX separation capacity, reflecting the complementary roles of each technology within the integrated flowsheet.

Halifax, Nova Scotia--(Newsfile Corp. - September 16, 2025) - Ucore Rare Metals Inc. (TSXV: UCU) (OTCQX: UURAF) ("Ucore" or the "Company") is pleased to announce the signing of a strategic technology collaboration agreement with Metallium Limited (ASX: MTM) (OTCQX: MTMCF).

Metallium's Flash Joule Heating ("FJH") is capable of upgrading rare earth mineral concentrates to Mixed Rare Earth Chlorides ("MREC"), which will then be refined into purified rare earth oxides utilizing Ucore's RapidSXTM technology at its Louisiana refinery. FJH provides a potential alternative to traditional approaches for generating mixed rare earth products. FJH has the potential to significantly expand potential feedstock sources for Ucore's refining facility.

The focus of Ucore's business is to restore rare earth refining which is a critical bottleneck in an evolving Western World integrated rare earth supply chain. With it's modular and scalable RapidSX technology supported by the US DoW, the complex task of separating individual rare earth oxides (REOs) from developing allied feedstock sources is the lynch pin. These reliable REE concentrate sources are fundamental and because RapidSX is feedstock-agnostic, the more sources of inputs, the greater the options for creating (REO) supply pathways.

The agreement formalises a strategic partnership to integrate Metallium's FJH process, which converts a wide range of rare earth-bearing materials into high-purity chloride intermediates, with Ucore's RapidSX™ separation platform, which is being scaled at the Strategic Metals Complex (SMC) in Louisiana. Together, the companies are targeting a modular U.S.-based refining solution that can process both conventional REE concentrates and alternative feedstocks such as magnet scrap, e-waste, and lighting waste, producing separated REOs including NdPr, Dy, and Tb, while also opening opportunities to recover other critical and precious metals.

Collaboration Scope

Under the agreement, Metallium and Ucore will:

- Collaborate on integrating Metallium's FJH-based chloride upgrading technology with Ucore's RapidSX™ separation platform across a wide range of feedstocks. The collaboration will explore opportunities to bypass conventional acid-leach circuits by converting REE-bearing feedstocks into enriched mixed rare earth chlorides ("MRECℓ or "EMRECs").

- The parties will also investigate the recovery of the highly strategic heavy REE terbium (Tb) and other high-value elements from lighting waste and phosphor powders and separately undertake joint R&D on recovering non-REE metal chlorides such as Au, Sb, Sn and Cu from e-waste brines.

Next Steps

- The collaboration will advance through a staged program of test work and pilot operations. In the first stage, bench-scale testing will focus on processing Ucore-supplied rare earth concentrate through Metallium's FJH system to produce mixed REE chlorides; the conversion of magnet scrap into chlorides containing neodymium, praseodymium, dysprosium and terbium; and the extraction of terbium from lighting waste.

- In the second stage, pilot-scale production will involve pilot campaigns to produce mixed REE chlorides (MRECℓ) for processing at Ucore's Commercial Demonstration Plant in Kingston, Ontario, Canada.

- This second stage will include the processing of mixed metal chlorides derived from e-waste processed using FJH.

Figure 1: Ucore Chief Operating Officer Michael Schrider & Flash Metals USA (FMU) President Steve Ragiel at FMU's lab in Texas

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1119/266618_f11461bb64d259ac_001full.jpg

Metallium Managing Director & CEO, Michael Walshe, commented: "Ucore is constructing one of the most advanced REE downstream separation facilities in North America, and this strategic agreement positions us a key participant in that supply chain. Our FJH platform can help unlock feedstocks that are currently stranded or heavily discounted, especially those rich in heavy REEs."

Ucore Chairman & CEO, Pat Ryan, commented: "We are excited to explore the integration of Metallium's metal recovery platform with our RapidSX™ This collaboration directly supports the U.S. Government's strategic objective of developing Western-aligned separation capabilities that are scalable, flexible, and feedstock-agnostic. Our goal is to deliver consistent, high-purity rare earth outputs suitable for critical defense and commercial applications."

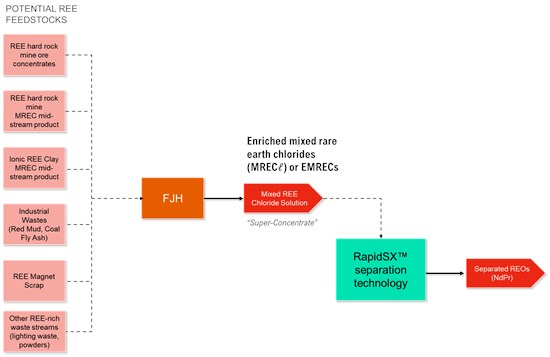

Illustrative Flowsheet

Metallium's FJH technology acts as an upstream upgrading step, producing chloride intermediates that are then refined into individual REEs using Ucore's RapidSX™ separation platform. The diagram below presents a modular rare earth element (REE) refining pathway capable of processing a wide range of REE-bearing feedstocks. These include primary mineral concentrates, mid-stream MREC from ionic clays, recycled materials (e.g. rare earth magnet scrap), and industrial residues (e.g. red mud, coal fly ash).

Figure 2: Integrated FJH-RapidSX™ Flowsheet for Multi-Feedstock Rare Earth Refining

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1119/266618_f11461bb64d259ac_002full.jpg

Using Metallium's proprietary FJH process, these inputs are upgraded into high-purity mixed REE chloride intermediates. The resulting solution is then conditioned and processed via Ucore's RapidSX™ separation platform to produce individual rare earth oxides (REOs), such as neodymium-praseodymium (NdPr). This integrated flowsheet represents a scalable, non-Chinese alternative to traditional sulphate-leach and solvent extraction processes, suitable for both conventional and unconventional REE sources.

The binding agreement is for a term of 12 months from the date of signing, September 13, 2025. Each party will enter good faith discussions to explore the potential of a future commercial arrangement for future collaboration. Each party shall retain all rights to their technology and binding non-disclosure agreements are in place between the parties. There are no commercial arrangements by way of fees or consideration associated with this collaboration agreement.

# # #

About Ucore Rare Metals Inc.

Ucore is focused on rare- and critical-metal resources, extraction, beneficiation, and separation technologies with the potential for production, growth, and scalability. Ucore's vision and plan is to become a leading advanced technology company, providing best-in-class metal separation products and services to the mining and mineral extraction industry.

Through strategic partnerships, this plan includes disrupting the People's Republic of China's control of the North American REE supply chain through the near-term development of a heavy and light rare-earth processing facility in the US State of Louisiana, subsequent SMCs in Canada and Alaska and the longer-term development of Ucore's

Ucore is listed on the TSXV under the trading symbol "UCU" and in the United States on the OTC Markets' OTCQX® Best Market under the ticker symbol "UURAF."

For further information, please visit www.ucore.com.

Forward-Looking Statements

This press release includes certain statements that may be deemed "forward-looking statements". All statements in this release (other than statements of historical facts) that address future business development, technological development and/or acquisition activities (including any related required financings), timelines, events, or developments that the Company is pursuing are forward-looking statements. Although the Company believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance or results, and actual results or developments may differ materially from those in forward-looking statements.

Regarding the disclosure in the press release above about the government support for Ucore, the Company has assumed that the applicable projects (including each of the associated milestones) will be completed satisfactorily and in accordance with the respective agreements or letters of intent (as applicable) for such government support. For additional risks and uncertainties regarding the Company, its business activities, its ability to qualify for and receive any additional funding from any U.S. or Canadian government, the CDF and the aforementioned projects (generally), see the risk disclosure in the Company's MD&A for Q1 2025 (filed on SEDAR+ on May 9, 2025) (www.sedarplus.ca) as well as the risks described below. As noted above, the execution of a Definitive Offtake Agreement will be conditional upon the parties agreeing on commercial terms, among other conditions precedent.

Regarding the disclosure above in the "About Ucore Rare Metals Inc." section, the Company has assumed that it will be able to procure or retain additional partners and/or suppliers, in addition to Innovation Metals Corp. ("IMC"), as suppliers for Ucore's expected future SMCs. Ucore has also assumed that sufficient external funding will be found to continue and complete the ongoing research and development work required at the CDF and also later prepare a new National Instrument 43-101 technical report that demonstrates that Bokan is feasible and economically viable for the production of both REE and co-product metals and the then prevailing market prices based upon assumed customer offtake agreements. Ucore has also assumed that sufficient external funding will be secured to continue the development of the specific engineering plans for the SMCs and their construction and eventual commissioning and operations. Factors that could cause actual results to differ materially from those in forward-looking statements include, without limitation: IMC failing to protect its intellectual property rights in RapidSX™; RapidSX™ failing to demonstrate commercial viability in large commercial-scale applications; Ucore not being able to procure additional key partners or suppliers for the SMCs; Ucore not being able to raise sufficient funds to fund the specific design and construction of the SMCs and/or the continued development of RapidSX™; adverse capital-market conditions; unexpected due-diligence findings; the emergence of alternative superior metallurgy and metal-separation technologies; the inability of Ucore and/or IMC to retain its key staff members; a change in the legislation in Louisiana or Alaska and/or in the support expressed by the Alaska Industrial Development and Export Authority (AIDEA) regarding the development of Bokan; the availability and procurement of any required interim and/or long-term financing that may be required; and general economic, market or business conditions.

Neither the TSXV nor its Regulation Services Provider (as that term is defined by the TSXV) accept responsibility for the adequacy or accuracy of this release.

CONTACTS

Mr. Peter Manuel, Ucore Vice President and Chief Financial Officer, is responsible for the content of this news release and may be contacted at 1.902.482.5214.

For additional information, please contact:

Mark MacDonald

Vice President, Investor Relations

Ucore Rare Metals Inc.

1.902.482.5214

mark@ucore.com

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/266618