First Atlantic Nickel Reports Highest Awaruite (Nickel-Iron-Cobalt Alloy) DTR Grades and Recovery to Date From Expansion Drilling at Pipestone XL Nickel Alloy Project

Rhea-AI Summary

First Atlantic Nickel (OTCQB: FANCF) reported DTR metallurgical results from Phase 2X drilling at the RPM Zone, Pipestone XL. Hole AN-25-10 returned the highest magnetically recoverable nickel to date: 0.15% DTR Ni over 228 m from 0.22% total Ni, with 68.62% magnetic Ni recovery and a 10.48% mass pull. This is a 25% increase over the RPM Zone average DTR Ni of 0.12%. AN-25-10 ended in mineralization at 233 m after a clay-filled fault; follow-up, deeper eastward drilling toward Chrome Pond is planned. Metallurgical work continues, including chromium and cobalt recoveries, with updates expected in early 2026.

Positive

- 0.15% DTR Ni over 228 m in Hole AN-25-10

- 68.62% magnetic nickel recovery in AN-25-10

- 10.48% mass pull reduces feed mass ~90%

- 25% DTR Ni increase vs RPM Zone average

- Chromium present: average 0.29% Cr in concentrate

Negative

- Drilling halted at 233 m due to clay-filled fault

- AN-25-09 magnetic recovery 36.07% lowers zone average

- Reported DTR Ni grades remain low in absolute terms (<0.2% Ni)

News Market Reaction

On the day this news was published, FANCF declined 3.20%, reflecting a moderate negative market reaction.

Data tracked by StockTitan Argus on the day of publication.

Key Figures

Market Reality Check

Peers on Argus

Peers showed mixed moves: MNXXF up 3.38%, GARWF up 4.53%, ARLYF down 16.48%, GBMCF down 1.03%, SJRNF flat. With no momentum scanner hits and no same-day peer headlines, FANCF’s trading appeared more stock-specific than sector-driven.

Historical Context

| Date | Event | Sentiment | Move | Catalyst |

|---|---|---|---|---|

| Dec 04 | Drilling expansion | Positive | -2.1% | Phase 2X drill program expanded with four new holes at RPM Zone. |

| Dec 02 | Drill results | Positive | -3.2% | Hole AN-25-10 delivers highest DTR nickel grades and recovery to date. |

| Nov 18 | Conference marketing | Positive | -3.0% | Benchmark Week presentation on awaruite as smelter-free nickel-cobalt source. |

| Nov 06 | Conference marketing | Positive | +0.7% | Conference highlighting smelter-free processing and chromium byproduct potential. |

| Nov 03 | Drilling update | Positive | -3.9% | Phase 2X drilling expands lateral width and defines 4-km target at RPM. |

Recent operational and marketing updates have generally been positive yet often accompanied by negative next-day price reactions, suggesting a pattern of weak price alignment with favourable technical news.

Over the last few months, First Atlantic Nickel has focused on expanding and de‑risking the Pipestone XL Nickel Alloy Project. Drilling updates on Nov 3 and Dec 2 highlighted long awaruite intervals and rising DTR nickel grades, including 0.15% DTR Ni over 228 m with 68.62% recovery. Conference appearances on Nov 6 and Nov 18 emphasized smelter‑free processing and critical minerals positioning. A Dec 4 update expanded Phase 2X drilling. Despite constructive news flow, several of these events saw negative 24‑hour price reactions.

Market Pulse Summary

This announcement emphasizes record DTR nickel grades and recoveries at the RPM Zone, highlighted by Hole AN-25-10’s 0.15% DTR Ni over 228 m and 68.62% magnetic recovery, plus byproduct potential from chromium and cobalt. In recent months, the company has repeatedly expanded the Pipestone XL footprint and showcased awaruite’s smelter‑free advantages. Investors may focus on ongoing metallurgical work, future resource definition, and execution of planned step‑out drilling as key markers of project progression.

Key Terms

davis tube recovery technical

magnetic concentrate technical

pentlandite technical

smelting technical

flotation technical

chromite technical

ophiolite technical

AI-generated analysis. Not financial advice.

Hole AN-25-10 Delivers Highest DTR Nickel Grade and Magnetic Concentrate Performance at RPM Zone; Company Plans to Announce Additional Drilling Around Hole 10 with Optimized Drilling Designed to Continue Eastward Expansion Toward Chrome Pond

GRAND FALLS-WINDSOR, Newfoundland and Labrador, Dec. 02, 2025 (GLOBE NEWSWIRE) -- First Atlantic Nickel Corp. (TSXV: FAN) (OTCQB: FANCF) (FSE: P21) ("First Atlantic" or the "Company") is pleased to announce Davis Tube Recovery (“DTR”) metallurgical results from Phase 2X drill holes AN-25-09 and AN-25-10 at the RPM Zone within its Pipestone XL Nickel Alloy Project in central Newfoundland. Hole AN-25-10 has returned the highest magnetically recoverable nickel grades and recovery to date at the RPM Zone, averaging

Hole AN-25-10 intersected the highest-grade intervals to date at the RPM Zone, including

Unlike conventional nickel sulfide minerals such as pentlandite (Fe,Ni)₉S₈, which contain sulfur, a non-metallic chemical element that must be removed through secondary processes such as smelting or roasting prior to the refining stages required to produce nickel sulphate (NiSO4) for EV battery precursor cathode active materials (pCAM), awaruite (Ni₃Fe) is a naturally occurring nickel-iron-cobalt alloy that already exists in a reduced metallic state containing approximately

Please call 844-592-6337 or email rob@fanickel.com to connect with Rob Guzman, First Atlantic Nickel's Investor Relations, for questions or more information.

KEY HIGHLIGHTS:

- Best DTR Nickel Results to Date: Hole AN-25-10 returned

0.15% DTR Ni over 228 meters, the highest average magnetically recoverable nickel grade to date at the RPM Zone, calculated from1.44% Ni in magnetic concentrate with a10.48% mass pull. This represents a25% increase over the RPM Zone average of0.12% DTR Ni (calculated from1.29% Ni concentrate and9.25% mass pull). - Highest-Grade Intervals - Open at Depth: Hole AN-25-10 returned

0.17% DTR Ni from 8 to 59 meters (51 m), and0.16% DTR Ni from 215 to 236 meters (21 m), both the best interval grades to date. The drill hole stopped in mineralization at 233 meters due to a clay-filled fault zone with abundant magnetite. Follow-up drilling from new collar locations will test deeper near Hole AN-25-10. - Eastward Drilling Delivers Best Results: Hole AN-25-10, positioned 200 meters east of the previous best hole (AN-24-04:

0.14% DTR Ni over 366 meters), exceeded that benchmark. The eastward trend toward Chrome Pond, where historic sampling returned up to62.2% Cr₂O₃ - continues to yield the highest DTR Ni grades on the property. - High Nickel Recovery from Awaruite: Hole AN-25-10 achieved

68.62% magnetic nickel recovery, the best average recovery to date at the RPM Zone. Awaruite (Ni₃Fe) contains approximately77% nickel, or 2-3x the grade of common nickel sulfide minerals, enabling simpler magnetic concentration with less complicated flotation and supporting higher end-concentrate grades. - Additional Drilling Planned: The Company plans to announce additional drilling around Hole AN-25-10. Optimized drilling is designed to test deeper and continue expansion eastward. The eastern extension toward Chrome Pond remains open and is a high priority target.

- Chromium Co-Product Potential: Chromium occurs with awaruite nickel in all RPM Zone drill holes, averaging

0.29% Cr and0.15% DTR chromium. Mineralogy studies are underway to identify chromium mineral content and assess recovery and concentration potential for a chromium by-product concentrate. - Metallurgical Program Expanding: Mineralogy, recovery, and concentrate testing are ongoing. Chromite has been identified as the chromium-bearing mineral, and the Company is evaluating recovery methods and processing options. Updates on recovery, separation, and preliminary nickel, chromium, and cobalt concentrate products are anticipated in early 2026.

HOLE AN-25-10 DELIVERS BEST RESULTS TO DATE ON EASTERN EXTENSION

Table 01: Pipestone XL Nickel Alloy Project - Summary of Assay Results and DTR Metallurgical Test Results for Drill Hole AN-25-10 (RPM Zone)

| Hole ID | From (m) | To (m) | Interval (m) | Mass Pull (%) | Nickel - Magnetic Concentrate Grade Ni ( %) | Nickel - Total Grade Ni (%) | DTR Nickel Grade - Magnetically Recovered Ni (%) | Total Nickel Recovery (%) | Chromium - Magnetic Concentrate Grade Cr (%) | Chromium Total Grade Cr (%) | DTR Chromium Grade - Magnetically Recovered Cr (%) | Cobalt - Magnetic Concentrate Grade Co (%) |

| AN-25-10 | 8 | 236 | 228 | 10.48 | 1.44 | 0.22 | 0.15 | 68.62 | 1.54 | 0.29 | 0.16 | 0.05 |

| including | 8 | 59 | 51 | 9.47 | 1.76 | 0.21 | 0.17 | 79.80 | 1.55 | 0.29 | 0.15 | 0.06 |

| 215 | 236 | 21 | 9.21 | 1.72 | 0.22 | 0.16 | 71.74 | 1.70 | 0.29 | 0.16 | 0.06 | |

| Including "Up To" | 15.20 | 2.08 | 0.26 | 0.19 | 99.80 | 2.85 | 0.46 | 0.33 | 0.07 | |||

Hole AN-25-10 was positioned 200 meters east of Hole AN-24-04, the Company's previous best drill hole (

Hole AN-25-10 intersected the highest-grade intervals to date at the RPM Zone, including

Drilling was halted at 233 meters after the hole encountered a clay-filled fault zone that caused complete loss of water circulation and excessive torque on the drill rods. Drill cuttings contained abundant magnetite that could not be washed from the borehole, preventing further advancement without risking equipment damage or the drill becoming irretrievably stuck downhole. Although the fault zone required suspension of drilling, the abundance of magnetite in the drill cuttings is encouraging, as awaruite commonly forms alongside magnetite during serpentinization. The hole ended in mineralization grading

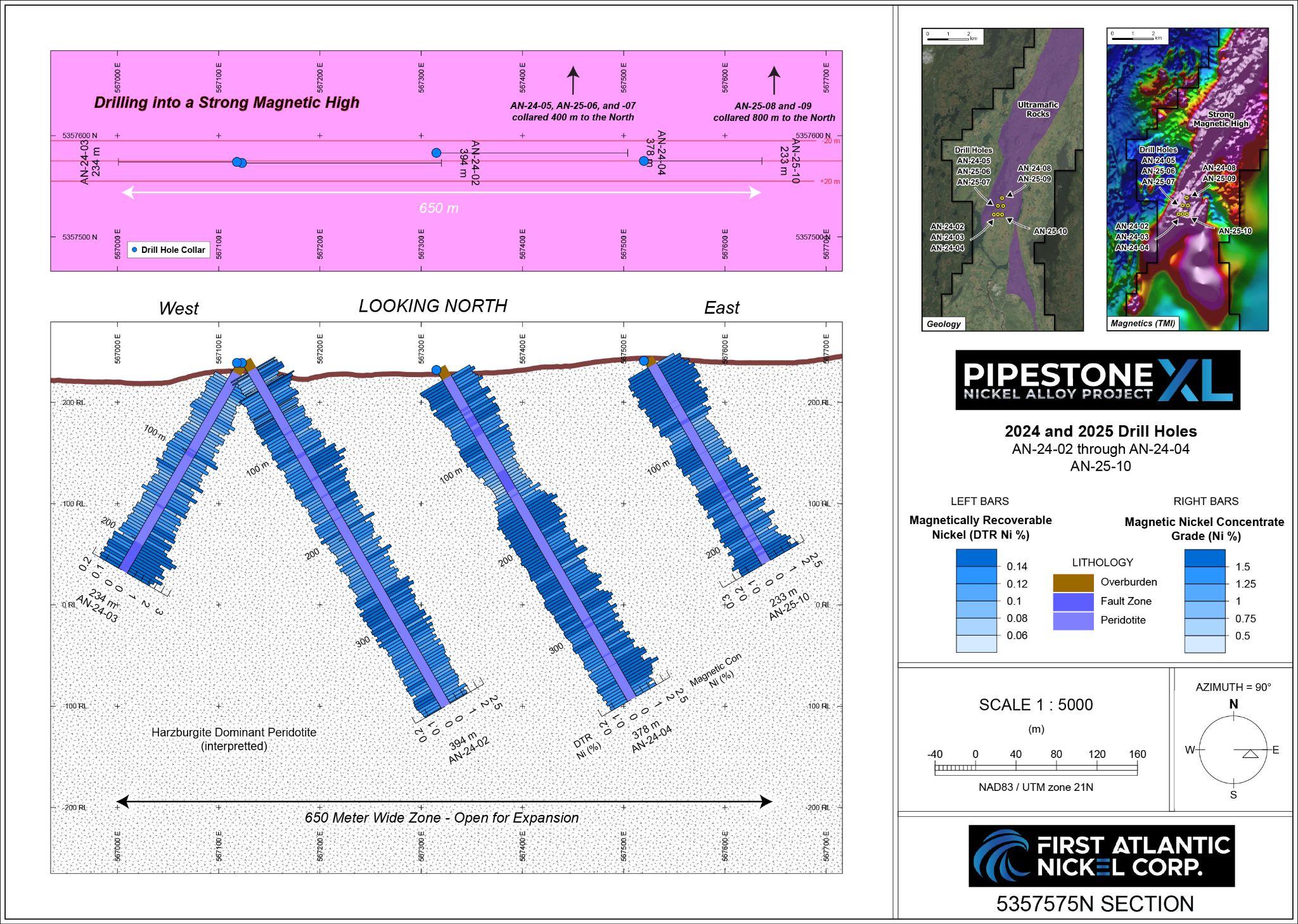

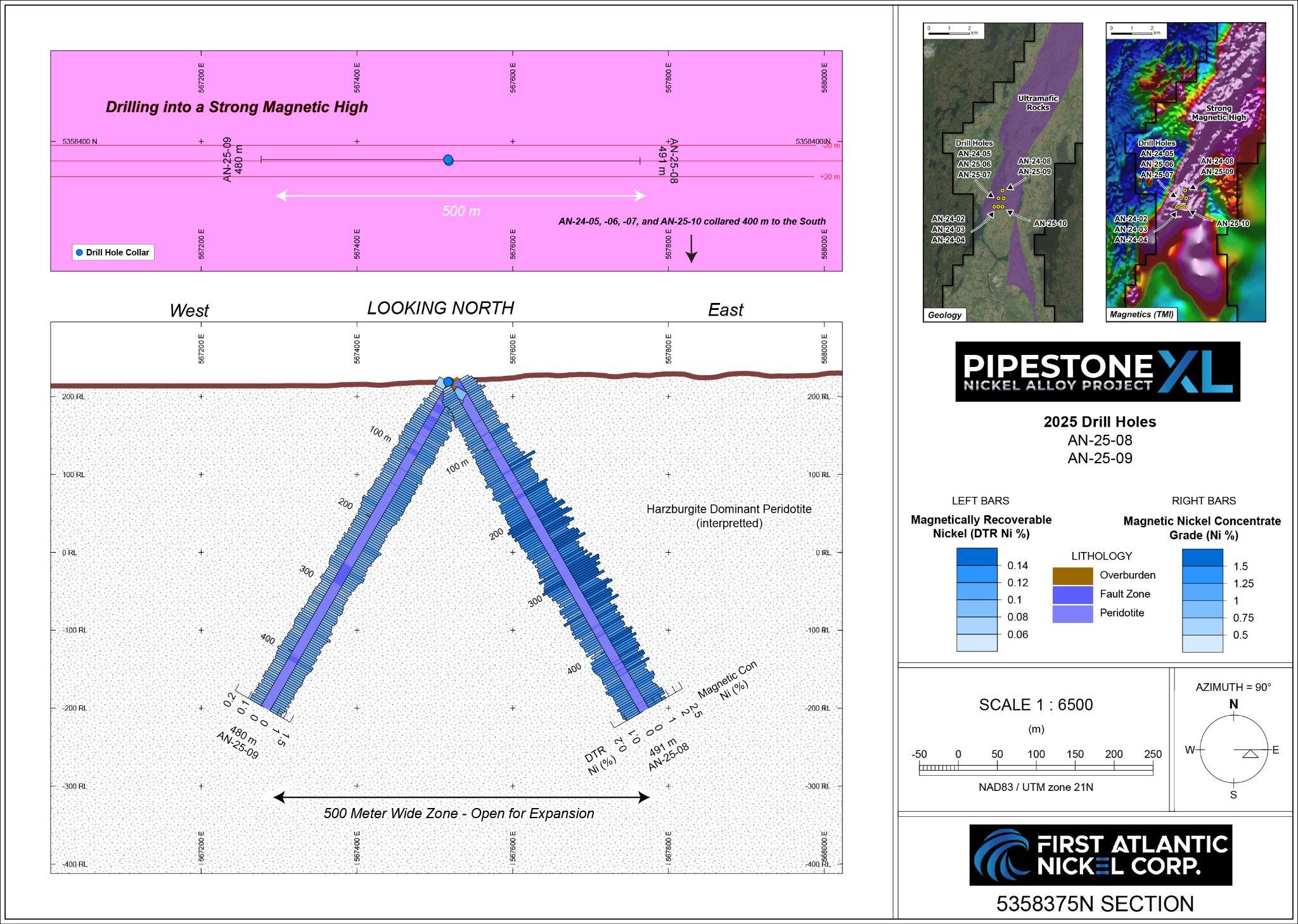

Figure 01: Cross-sectional view of the RPM Zone Hole AN-24-02 to AN-24-04 and AN-25-10, showing the distribution of magnetic concentrate and DTR nickel values. Hole AN-25-10 averages

Table 02: Drill Hole Collar Location Information

| Hole ID | Easting (UTM) | Northing (UTM) | Elevation (m) | Azimuth (°) | Dip (°) | Depth (m) |

| AN-25-09 | 567517 | 5358377 | 219 | 270 | -60 | 480 |

| AN-25-10 | 567520 | 5357575 | 241 | 90 | -60 | 233 |

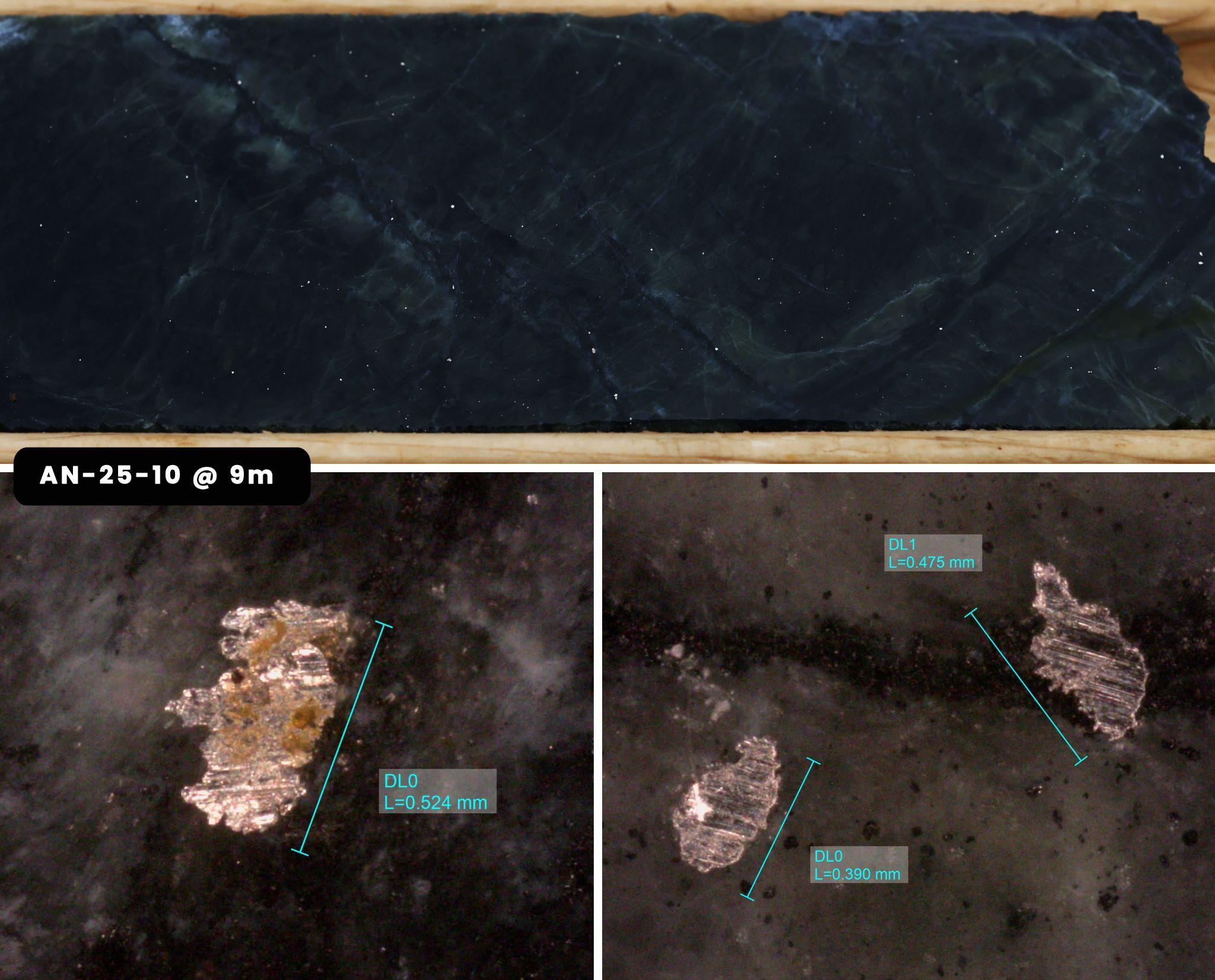

Figure 02: Drill core from Hole AN-25-10 at 9 meters, showing disseminated awaruite (nickel-iron alloy) in serpentinized peridotite (top); photomicrographs show awaruite grains up to ~500 microns in size (bottom).

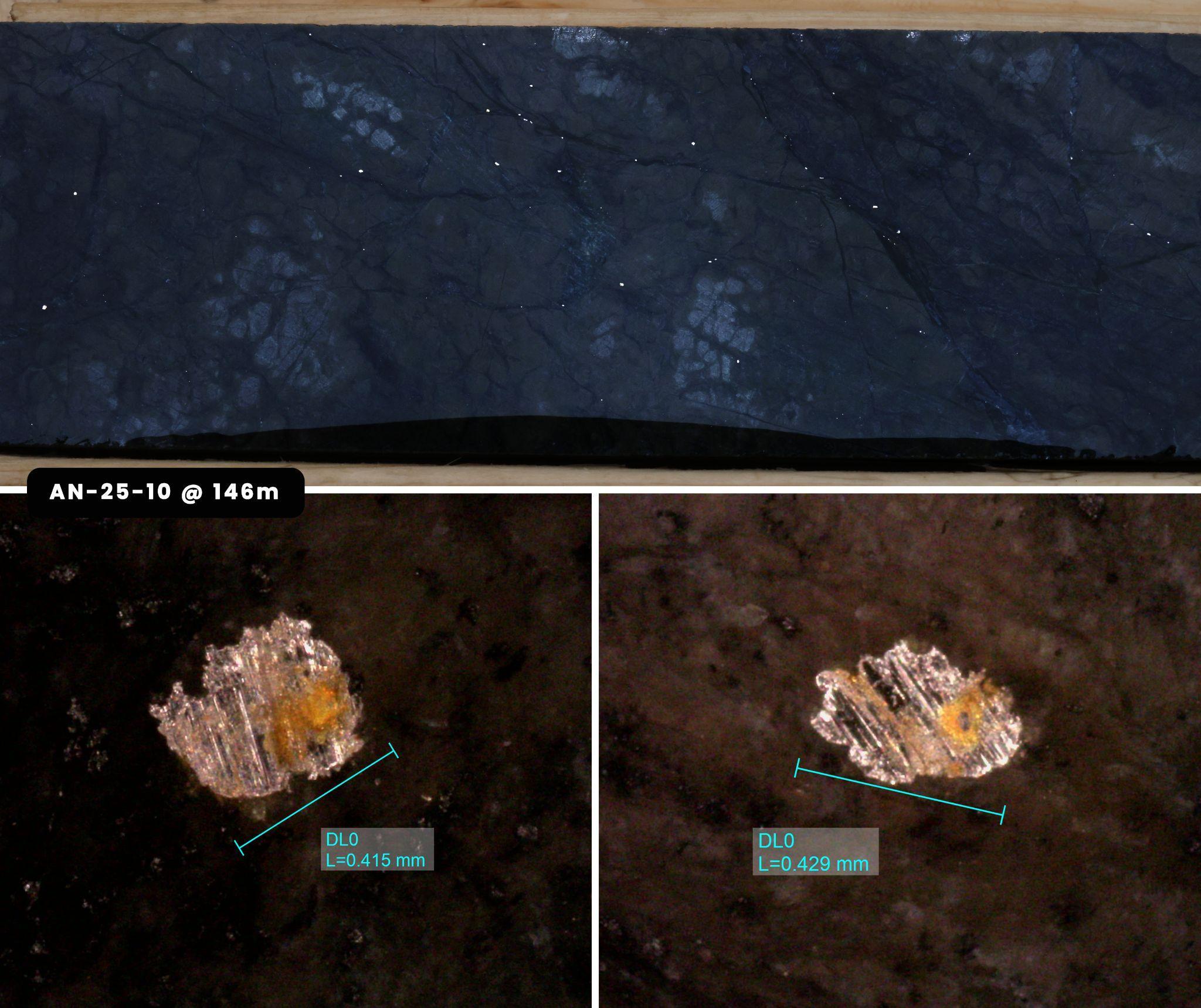

Figure 03: Drill core from Hole AN-25-10 at 146 meters, showing disseminated awaruite (nickel-iron alloy) in serpentinized peridotite (top); photomicrographs show awaruite grains up to ~450 microns in size (bottom).

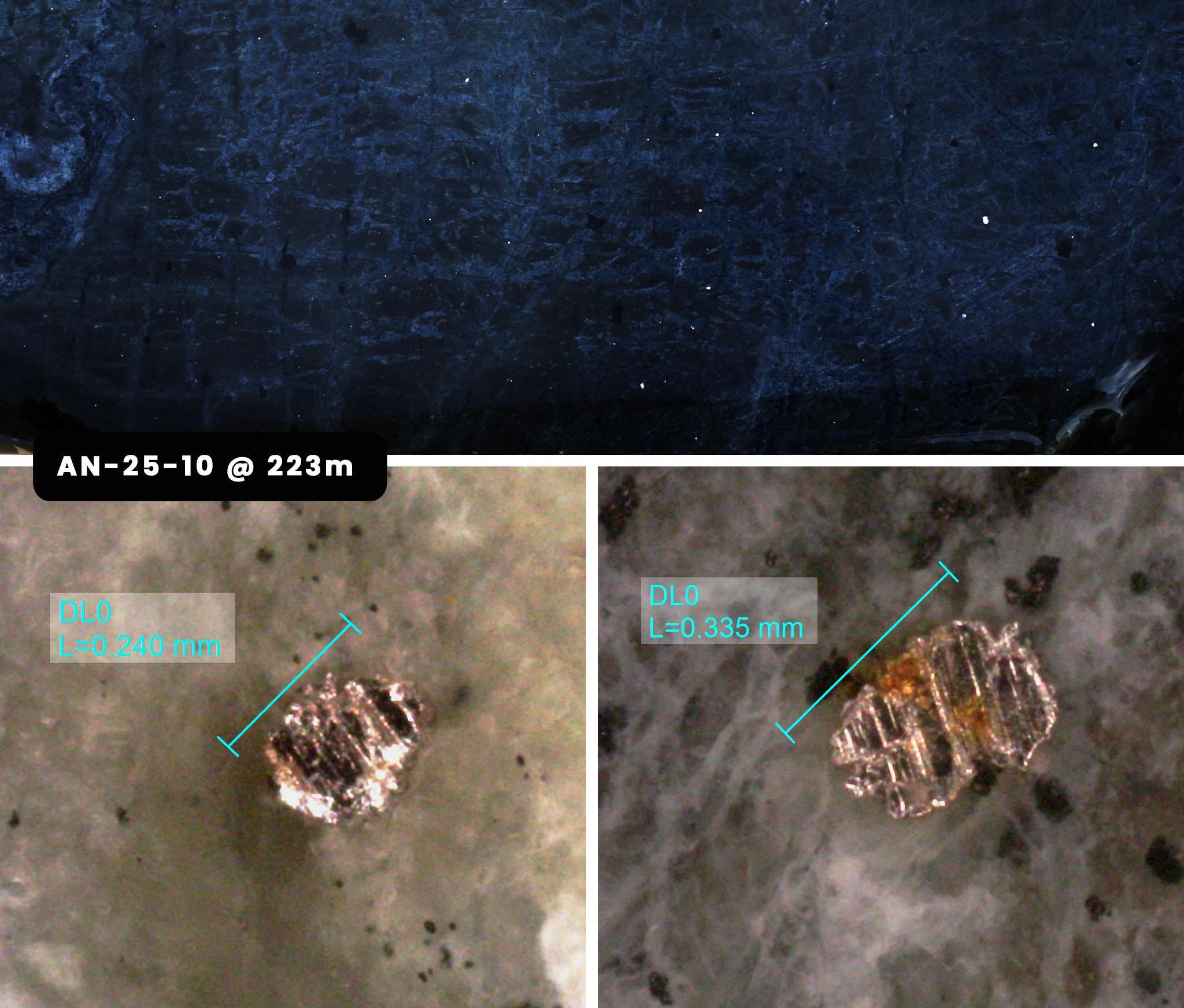

Figure 04: Drill core from Hole AN-25-10 at 233 meters, showing disseminated awaruite (nickel-iron alloy) in serpentinized peridotite (top); photomicrographs show awaruite grains up to ~350 microns in size (bottom).

Hole AN-25-09, located 800 meters north of the discovery drilling on Section S1, was drilled from the same collar location as Hole AN-25-08 but oriented in the opposite direction. This hole tested westward toward Pipestone Pond on Section S3 and intersected continuous mineralization over its entire 480-meter length, returning

The westward orientation of AN-25-09, drilled prior to refined structural interpretation, was not optimally oriented to test the true width of the awaruite-bearing body. Despite this, the hole provided valuable geological information confirming the westward-dipping system, consistent with results from Hole AN-25-07, which was also drilled westward on Section S2. The successful DTR results from eastward-oriented holes, compared with the sub-optimal westward orientation of AN-25-07 and AN-25-09, confirm that eastward-oriented drilling is essential to test the true width of the mineralized body and continues to deliver the best grades on the property.

Table 03: Pipestone XL Nickel Alloy Project - Summary of Assay Results and DTR Metallurgical Test Results for Drill Hole AN-25-09 (RPM Zone)

| Hole ID | From (m) | To (m) | Interval (m) | Mass Pull (%) | Nickel - Magnetic Concentrate Grade Ni ( %) | Nickel - Total Grade Ni (%) | DTR Nickel Grade - Magnetically Recovered Ni (%) | Total Nickel Recovery (%) | Chromium - Magnetic Concentrate Grade Cr (%) | Chromium Total Grade Cr (%) | DTR Chromium Grade - Magnetically Recovered Cr (%) | Cobalt - Magnetic Concentrate Grade Co (%) |

| AN-25-09 | 9 | 483 | 474 | 9.00 | 0.93 | 0.23 | 0.08 | 36.07 | 1.61 | 0.28 | 0.14 | 0.06 |

| including | 42 | 417 | 375 | 9.03 | 0.95 | 0.23 | 0.09 | 37.16 | 1.57 | 0.26 | 0.14 | 0.06 |

| including "Up To" | 12.00 | 1.20 | 0.26 | 0.11 | 45.79 | 3.94 | 1.23 | 0.34 | 0.08 | |||

Figure 05: Cross-sectional view of the RPM Zone drill hole AN-25-08 and AN-25-09, located 800 meters north of discovery hole AN-24-02, showing the distribution of magnetic concentrate and DTR nickel values. Hole AN-25-08 averages

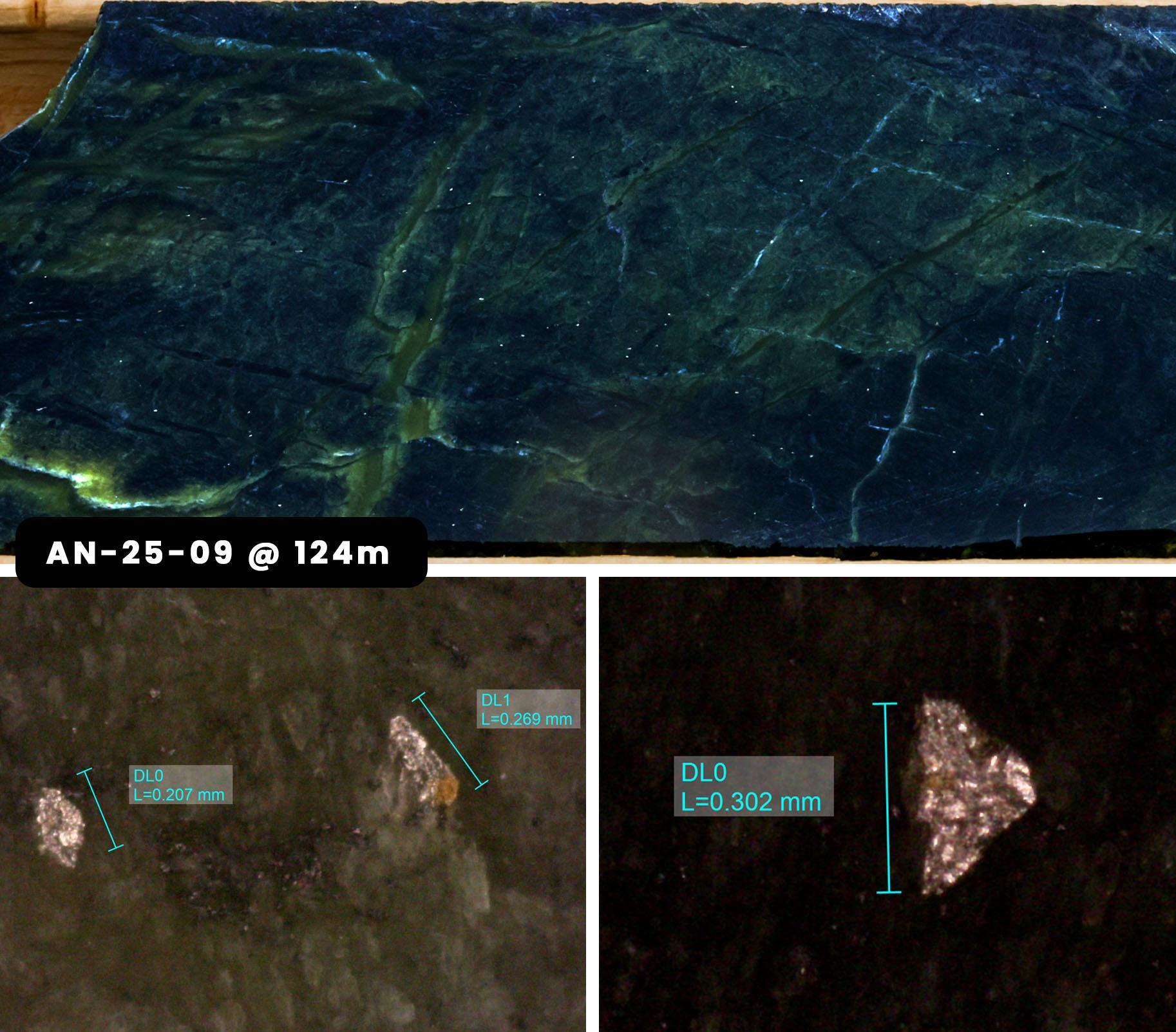

Figure 06: Drill core from Hole AN-25-09 at 124 meters, showing disseminated awaruite (nickel-iron alloy) in serpentinized peridotite (top); photomicrographs show awaruite grains up to ~300 microns in size (bottom).

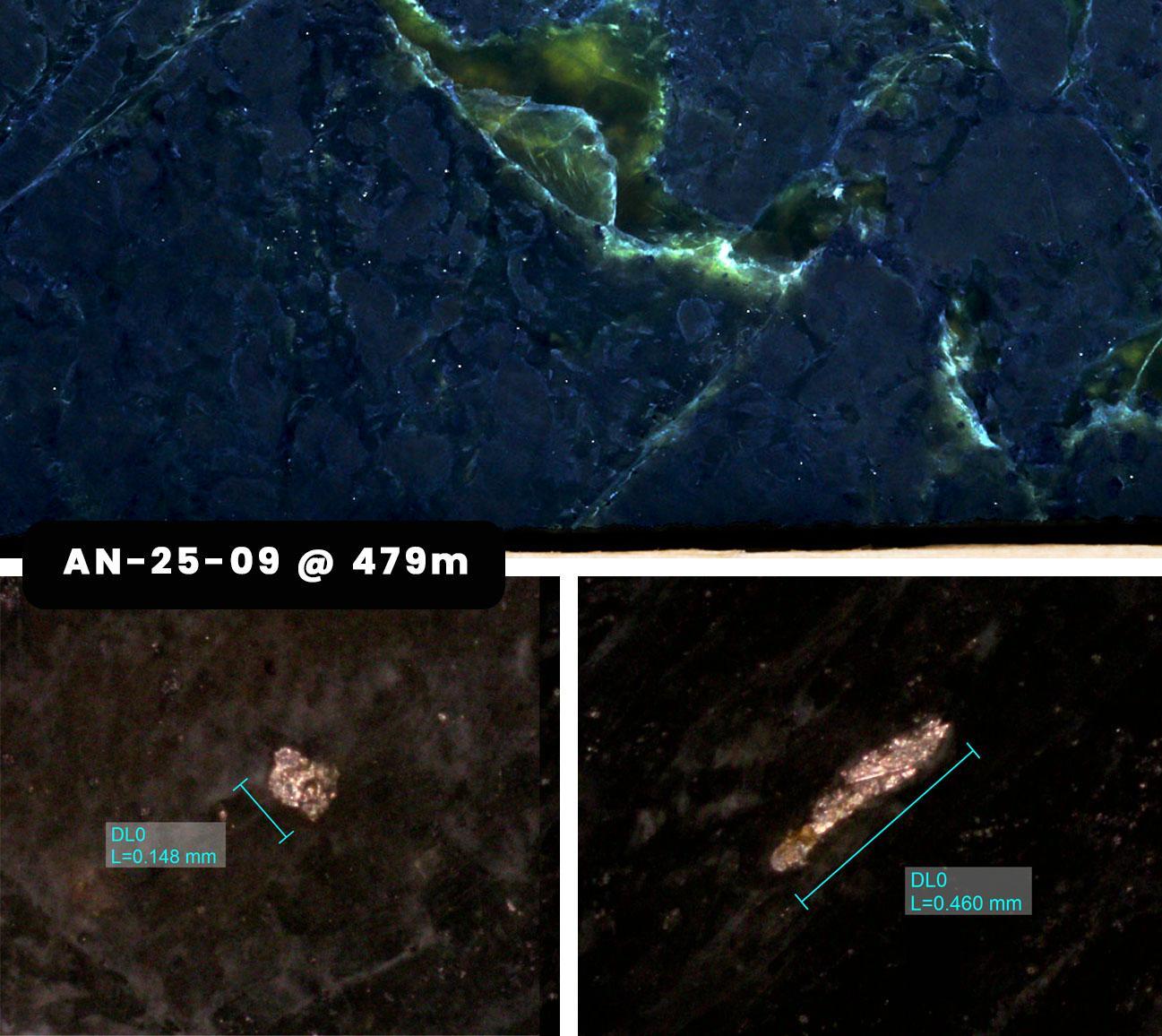

Figure 07: Drill core from Hole AN-25-09 at 479 meters, showing disseminated awaruite (nickel-iron alloy) in serpentinized peridotite (top); photomicrographs show awaruite grains up to ~450 microns in size (bottom).

AWARUITE NICKEL: HIGH RECOVERY FROM HIGH-GRADE MINERAL

Awaruite (Ni₃Fe) is a naturally occurring nickel-iron-cobalt alloy containing approximately

DTR metallurgical testing at the RPM Zone has achieved an average nickel recovery of

Unlike conventional nickel sulfide minerals such as pentlandite (Fe,Ni)₉S₈, which contain sulfur, a non-metal chemical element that takes-up weight and space within the mineral and needs to be removed through secondary processing such as high temperature smelting or roasting, awaruite's sulfur-free composition eliminates the need for smelting, roasting, or acid leaching. This positions the Pipestone XL Project as a potential domestic source of magnetically concentrated nickel that reduces reliance on overseas processing infrastructure.

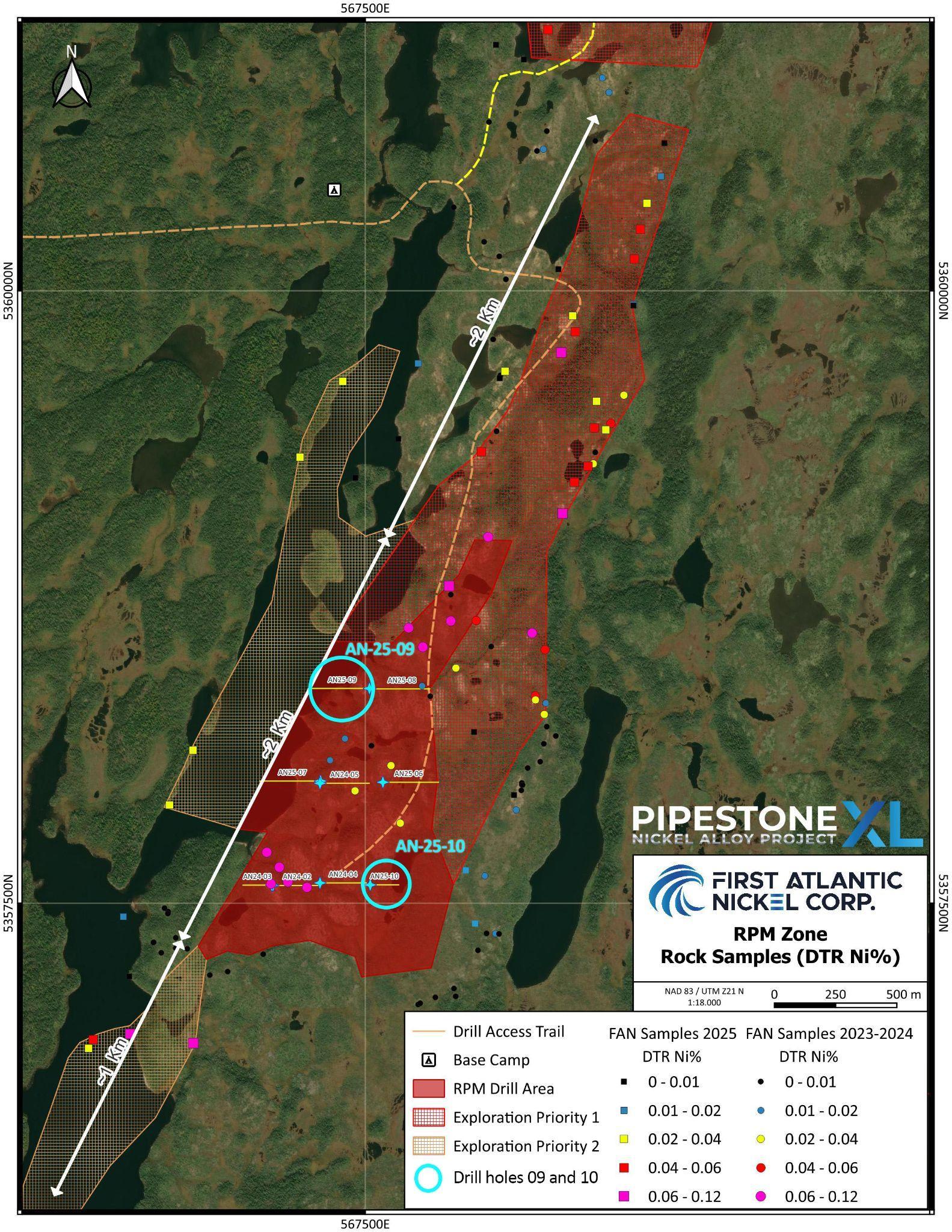

PHASE 2X DRILLING PROGRAM UPDATE

The Phase 2X drilling program continues to expand the RPM Zone within the 4-kilometer strike length target area announced October 21, 2025. To date, approximately 3,500 meters of drill core from the RPM Zone have returned positive magnetically recoverable nickel results. Reported holes averaging

The Company plans to announce additional drilling targeting multiple directions:

- Eastern Extension (High Priority): Following the exceptional results from Hole AN-25-10, additional drilling from optimized collars designed to penetrate deeper will target the zone beyond where the hole was halted, continuing the eastward expansion toward the historic Chrome Pond chromite prospect. The eastward trend has consistently delivered the best magnetically recoverable nickel grades on the property.

- Northern Extension: Systematic step-outs north of Section S3 will continue to test the 4-kilometer strike length potential outlined by DTR surface sampling.

- Southern Extension: Approximately 1 kilometer of southern extension potential has been identified in areas now reinterpreted as ultramafic peridotites hosting awaruite.

CHROMIUM CO-PRODUCT AND METALLURGICAL PROGRAM

Chromium occurs disseminated with the awaruite nickel alloy in all RPM Zone drill hole intervals, averaging

Table 04: RPM Zone - Complete Intervals for all Drill Holes Reported to Date

| Drill Hole | Zone | Section | From meters | To meters | Interval meters | Magnetically Recovered (DTR) Nickel % | Magnetic Concentrate Nickel Grade (Ni %) | Mass Pull (%) | Comment |

| AN 24 - 02 | RPM | S1 | 11.0 | 394.1 | 383.1 | 0.13 | 1.37 | 9.50 | NR - March 12, 2025 |

| AN 24 - 03 | RPM | S1 | 18.0 | 234.0 | 216.0 | 0.11 | 1.32 | 9.12 | NR - April 15, 2025 |

| AN 24 - 04 | RPM | S1 | 12.0 | 378.0 | 366.0 | 0.14 | 1.46 | 9.53 | NR- June 24, 2025 |

| AN 24 - 05 | RPM | S2 | 6.0 | 357.0 | 351.0 | 0.12 | 1.47 | 8.21 | NR - July 9, 2025 |

| AN 25 - 06 | RPM | S2 | 5.65 | 453 | 447.35 | 0.11 | 1.27 | 9.02 | NR - August 12, 2025 |

| AN 25 - 07 | RPM | S2 | 9 | 495 | 486.0 | 0.09 | 0.97 | 9.60 | NR - October 23, 2025 |

| AN 25 - 08 | RPM | S3 | 11 | 491 | 480.0 | 0.12 | 1.35 | 8.79 | NR - October 23, 2025 |

| AN 25 - 09 | RPM | S3 | 9 | 483 | 474.0 | 0.08 | 0.93 | 9.0 | NR - Dec 2, 2025 |

| AN 25 - 10 | RPM | S1 | 8 | 236 | 228 | 0.15 | 1.44 | 10.48 | NR - Dec 2, 2025 |

| TBA | |||||||||

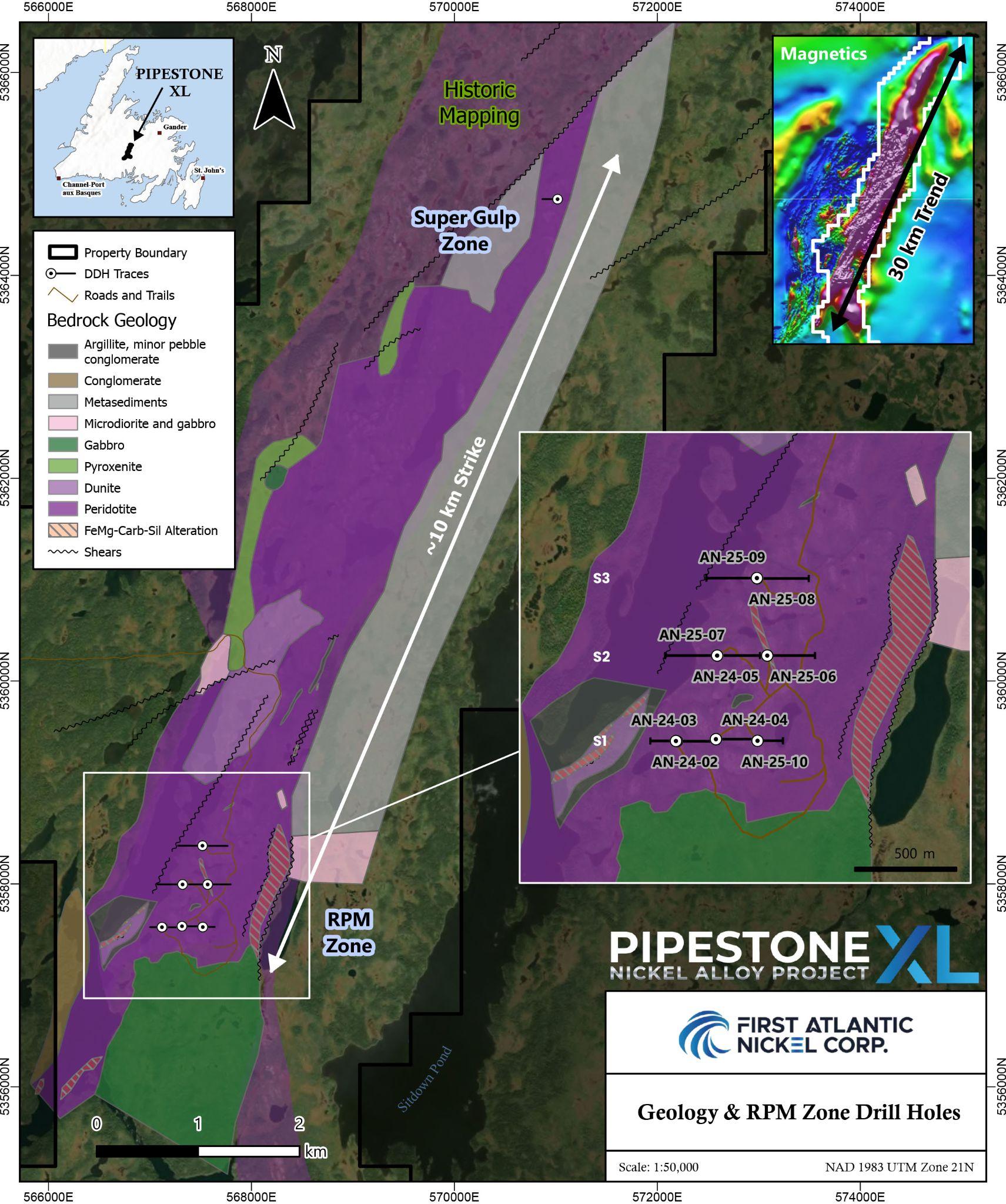

Figure 08: Phase 2X drill plan map showing expanded target areas - RPM, RPM South, and RPM North, within the 30 km Pipestone XL Nickel Alloy Project.

Figure 09: Phase 2X drill plan map at the RPM Zone showing the 800-meter drill-confirmed strike length and the open 10-kilometer strike extension to Super Gulp within the 30-kilometer Pipestone XL nickel trend.

AWARUITE - RARE & PURE NATURAL NICKEL-IRON-COBALT ALLOY MINERAL

The sulfur-free nature of awaruite (Ni₃Fe), a naturally occurring nickel-iron-cobalt alloy already in metallic form, eliminates the need for secondary processes such as smelting, roasting or acid leaching that are typical of sulfide or laterite nickel ores. Unlike sulfides, which are not natural alloys, awaruite avoids the challenge of sourcing smelter capacity—a bottleneck in North America's nickel supply chain. With an average nickel grade of approximately

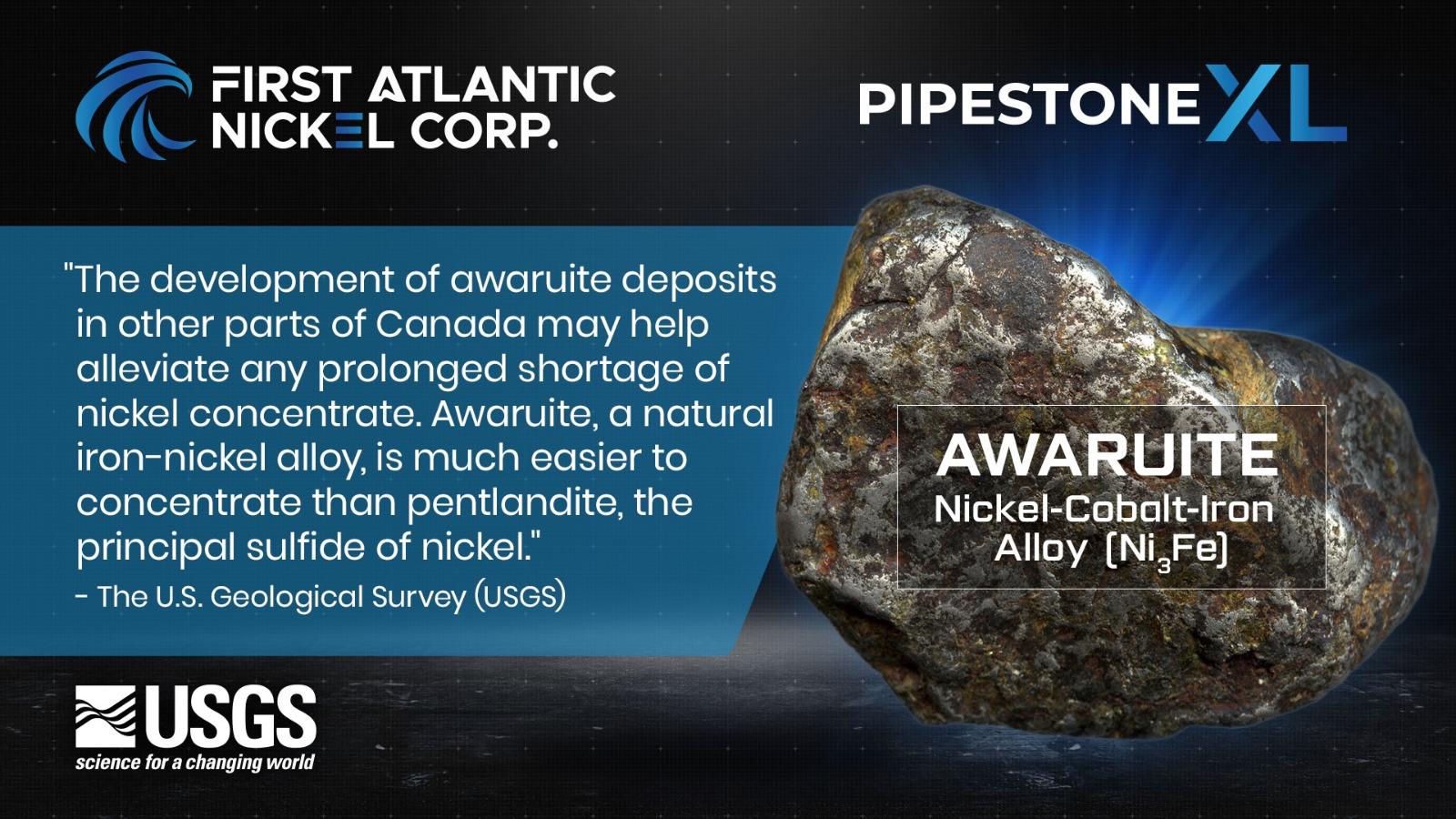

Awaruite eliminates the electricity requirements, emissions, and environmental impacts associated with conventional smelting, roasting or acid leaching processes of common nickel minerals. Moreover, awaruite's sulfur-free composition removes the risks of acid mine drainage (AMD) and related permitting challenges commonly posed by sulfide minerals. As noted by the United States Geological Survey (USGS) in 2012: "The development of awaruite deposits in other parts of Canada may help alleviate any prolonged shortage of nickel concentrate. Awaruite, a natural iron-nickel alloy, is much easier to concentrate than pentlandite, the principal sulfide of nickel."

Figure 10: Quote from USGS on Awaruite Deposits in Canada

DAVIS TUBE RECOVERY (DTR) METALLURGICAL TEST

Davis Tube Recovery (DTR) is a laboratory method that uses magnets to separate magnetic and non-magnetic material from a sample, similar to commercial magnetic separators used in mining operations. The percentage of magnetic mass recovered (mass pull) is used together with the assayed grade of the magnetic fraction to calculate the magnetically recoverable nickel.

DTR nickel percentage is calculated by: Mass Pull (%) × Magnetic Nickel Concentrate Grade (%). This represents the portion of nickel that can be recovered through magnetic separation and is not equivalent to a standard assay result. DTR results can vary based on equipment settings and technological advancements.

The Company has released a new educational video that breaks down the Davis Tube Recovery (DTR) test into five simple steps. This video is a valuable resource for anyone interested in understanding mineral exploration. Please visit https://www.youtube.com/watch?v=q3zsgDtLWns to view the video.

Figure 11: Davis Tube Recovery (DTR) Metallurgical Test 5 Step Process

https://www.globenewswire.com/NewsRoom/AttachmentNg/bcae86c9-5e0e-4262-8557-bd576dede2a0

Investor Information

The Company's common shares trade on the TSX Venture Exchange under the symbol "FAN", the American OTCQB Exchange under the symbol "FANCF" and on several German exchanges, including Frankfurt and Tradegate, under the symbol "P21".

Investors can get updates about First Atlantic by signing up to receive news via email and SMS text at www.fanickel.com.

FOR MORE INFORMATION:

First Atlantic Investor Relations

Robert Guzman

Tel: +1 844 592 6337

rob@fanickel.com

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Disclosure

Adrian Smith, P.Geo., a director and the Chief Executive Officer of the Company is a qualified person as defined by NI 43-101. The qualified person is a member in good standing of the Professional Engineers and Geoscientists Newfoundland and Labrador (PEGNL) and is a registered professional geoscientist (P.Geo.). Mr. Smith has reviewed and approved the technical information disclosed herein.

Analytical Method & QA/QC

Samples were split in half on site, with one half remaining in the core box for future reference and the other half securely packaged for laboratory analysis. The QA/QC protocol included the insertion of blanks, duplicates, and certified reference material (standards), with one QA/QC sample being inserted every 20 samples to monitor the precision and accuracy of the laboratory results. All analytical results successfully passed QA/QC screening at the laboratory, and all Company inserted standards and blanks returned results within acceptable limits.

Samples were submitted to Activation Laboratories Ltd. (“Actlabs”) in Ancaster, Ontario, an ISO 17025 certified and accredited laboratory operating independently of First Atlantic. Each sample was crushed, with a 250 g sub-sample pulverized to

The magnetic fractions are collected, dried, weighed and the magnetic fraction is fused with a lithium metaborate/tetraborate flux and lithium bromide releasing agent and then analyzed on a wavelength dispersive XRF for multiple elements including nickel, cobalt, iron and chromium. The magnetically recovered nickel grade was then calculated by multiplying the XRF fusion nickel value by the weight of the magnetic fraction and dividing by the total recorded feed weight or magnetic mass pulled from the sample.

True widths are currently unknown. However the nickel bearing ultramafic ophiolite and peridotite rocks being targeted and sampled in the Phase 1 drilling program at the Atlantic Nickel Project are mapped on surface and in drilling as several hundred meters to over 1 kilometer wide and approximately 30 kilometers long.

Forward-looking statements:

This news release may include "forward-looking information" under applicable Canadian securities legislation. Such forward-looking information reflects management's current beliefs and are based on a number of estimates and/or assumptions made by and information currently available to the Company that, while considered reasonable, are subject to known and unknown risks, uncertainties, and other factors that may cause the actual results and future events to differ materially from those expressed or implied by such forward-looking information.

Forward-looking information in this news release includes, but is not limited to: statements regarding: the timing, scope and results of the Company’s Phase 1 and Phase 2 work and drilling programs (including follow-up drilling around Hole AN-25-10 and continued expansion toward Chrome Pond); future project developments; the Company’s objectives, goals, and future plans; statements and estimates of market conditions; the viability of magnetic separation as a low-impact processing method for awaruite; the strategic and economic implications of the Company’s projects; and expectations regarding future developments and strategic plans. Forward-looking information is based on, among other things, assumptions regarding: the continuity of mineralization and geology suggested by drilling and sampling to date; metallurgical recoveries and magnetic separation performance continuing to be consistent with test results; the availability of drill rigs, services, personnel and supplies; permitting and regulatory timelines; prevailing and future nickel, cobalt and chromium prices and demand; and the Company’s ability to obtain financing on reasonable terms to carry out planned exploration and metallurgical programs.

Readers are cautioned that such forward-looking information are neither promises nor guarantees and are subject to known and unknown risks and uncertainties including, but not limited to, general business, economic, competitive, political and social uncertainties, uncertain and volatile equity and capital markets, lack of available capital, actual results of exploration activities, environmental risks, future prices of base and other metals, operating risks, accidents, labour issues, delays in obtaining governmental approvals and permits, and other risks in the mining and clean energy industries. Additional factors and risks including various risk factors discussed in the Company’s disclosure documents which can be found under the Company’s profile on http://www.sedarplus.ca. Should one or more of these risks or uncertainties materialize, or should assumptions underlying the forward-looking statements prove incorrect, actual results may vary materially from those described herein as intended, planned, anticipated, believed, estimated or expected.

The Company is presently an exploration stage company. Exploration is highly speculative in nature, involves many risks, requires substantial expenditures, and may not result in the discovery of mineral deposits that can be mined profitably. Furthermore, the Company currently has no mineral reserves on any of its properties. As a result, there can be no assurance that such forward-looking statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. The Company undertakes no obligation to update forward-looking information, except as required by applicable securities laws.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

___________________

1 https://fpxnickel.com/news/fpx-nickel-delivers-pfs-for-baptiste-nickel-project-with-after-tax-npv-of-us2-01-billion-and-18-6-irr/

2 https://www.sciencedirect.com/science/article/abs/pii/S0892687522003648

3 https://fpxnickel.com/projects-overview/what-is-awaruite/

Photo accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/8ed66821-c421-4180-be0b-4be846d81a0e

https://www.globenewswire.com/NewsRoom/AttachmentNg/92003ac4-70ce-4a6c-bce8-9b4c960de93a

https://www.globenewswire.com/NewsRoom/AttachmentNg/4f973b7a-c089-41ba-9ec9-b6d5354c74ea

https://www.globenewswire.com/NewsRoom/AttachmentNg/f3853087-d51c-4bde-9f08-356d1ef431af

https://www.globenewswire.com/NewsRoom/AttachmentNg/0b8c4361-bd91-4926-ae01-18bc04242ad8

https://www.globenewswire.com/NewsRoom/AttachmentNg/34836d05-57a3-42a0-93a2-960a50ac9e74

https://www.globenewswire.com/NewsRoom/AttachmentNg/c50bc760-073e-4242-be68-51a6366a1d1f

https://www.globenewswire.com/NewsRoom/AttachmentNg/eed03870-4a98-4b7c-af4d-30d7e7963c43

https://www.globenewswire.com/NewsRoom/AttachmentNg/08ff0385-ddc8-4022-9a31-6aa12f988e7c

https://www.globenewswire.com/NewsRoom/AttachmentNg/0d4db0e9-e9ea-4b90-b52d-fd2ac015ff78

https://www.globenewswire.com/NewsRoom/AttachmentNg/bcae86c9-5e0e-4262-8557-bd576dede2a0