Nordson EFD Takes Assembly Automation to Center Stage at MD&M West, February 3 – 5, 2026

Key Terms

oem technical

epoxy technical

uv cure technical

printed circuit board substrate technical

needle bonding technical

drug delivery device technical

Multiple assembly automation demonstrations, precision fluid dispensing technologies and an Expert Speaker presentation rounds out their conference engagement

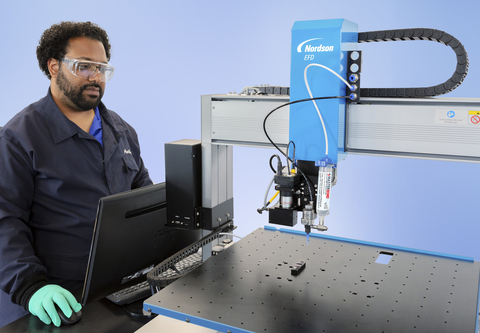

Nordson EFD will present multiple assembly automation demonstrations at MD&M West featuring PROX and PROPlus automated fluid dispensing systems for next-gen medical device prototyping and assembly operations.

Nordson EFD’s premier assembly automation demonstration exhibits the encapsulation of delicate embedded sensors in wearable technologies utilizing a 3-axis PROX system to dispense medical epoxy. Similar to water in viscosity, these critical epoxies encase sensor components that physically touch the skin and protect them from moisture and contaminants to ensure device reliability. A second live demonstration features a 4-axis PROPlus system simulating the underfill dispensing of a UV cure or thermal adhesive to fill gaps between a chip and its carrier or a finished package and the printed circuit board substrate. This crucial process protects electronics from thermal or environmental stresses and provides mechanical stability. A third automation demonstration exhibits a highly precise needle bonding application executed by two PICO Nexus controllers and two angled PICO XP jet valves. Integral to these demonstrations, the Nordson EFD line of Optimum fluid dispensing components ensure high quality manufacturing results.

Nordson EFD Experts speak at MD&M West on Tuesday, February 3, 2026

On Tuesday, February 3, 2026 from 10:15 AM - 11:00 AM in Room 206AB, Mark O’Shea and Anthony Buzzerio will present Cracking the Code on Assembly Automation (Session ID: MSC01) in the MedTech conference track: Manufacturing and Supply Chain. This educational session will address the two primary challenges — automation and assembly — that face the medical device industry as it continues to transition toward smaller, lighter products with embedded electronics. Mark O’Shea will discuss the unique engineering hurdles modern medical device design and the journey to industrializing fluid assembly processes through R&D, specialized domain expertise and technology advances. Anthony Buzzerio will follow O’Shea to present a real-world customer case story revealing the evolution of a complex drug delivery device from prototype to high-volume production.

About Nordson EFD

Nordson EFD designs and manufactures precision fluid dispensing systems for benchtop assembly processes and automated assembly lines. By enabling manufacturers to accurately and consistently apply the same amount of assembly fluid consistently to every part, EFD helps customers improve process control and throughput. In addition to producing high-quality fluid packaging syringe and cartridge systems, the company is also a leading formulator of specialty solder pastes for dispensing and printing applications. Nordson EFD is at the forefront of introducing Industry 4.0 efficiencies to the micro-dispensing marketplace, adding a new level of control and connectivity to its micro-dispensing solutions. Serving a wide variety of industries for more than 60 years, Nordson EFD has offices, application laboratories and technical support staff in 30 countries worldwide. To learn more, visit nordsonefd.com and follow us at linkedin.com/company/nordson-efd.

About Nordson Corporation

Nordson engineers, manufactures, and markets differentiated products and systems used for dispensing and processing adhesives, coatings, polymers, sealants and biomaterials; and for managing fluids, testing and inspecting for quality, treating surfaces and curing. These products are supported with extensive application expertise and direct global sales and service. We serve a wide variety of consumer non-durable, consumer durable and technology end markets including packaging, nonwovens, electronics, medical, appliances, energy, transportation, building and construction, and general product assembly and finishing. Founded in 1954 and headquartered in

View source version on businesswire.com: https://www.businesswire.com/news/home/20260120272285/en/

Belinda Jones, Press Contact

Tel: 860-399-1147; belinda.jones@hitechmarketing.com

Natalie Tomasso, Nordson EFD Global Marcom Contact

Tel: 401-431-7173; natalie.tomasso@nordsonefd.com

GLOBAL CONTACTS:

SEAsia: +65 6796 9522; sin-mal@nordsonefd.com

Source: Nordson EFD